Dyson Zone: Finetuning Filtration

For the first time, Dyson filters must withstand the challenges of the outdoors – more drastic temperature extremes, adverse weather conditions and on-the-go wear and tear. This, alongside specific space and weight constraints, drove the need to develop a new type of Dyson filter.

Filtration isn’t just about having a good filter; filter design, airflow pathways and machine sealing must work hand in hand. Frustrated by his Hoover Junior clogging on the first pass, James Dyson engineered the first cyclonic bagless vacuum cleaner that never lost suction, developing 5,127 prototypes in the process. Cyclones spin air to separate particles from airflow. Over time, by developing a multi-stage filtration process with a larger cone – the bin – plus multiple smaller cones, Dyson engineers created a system that is even more efficient. Over 30 years, this principle has developed into Dyson’s 6-stages of vacuum filtration, expelling only clean air.

From floors to air

Dyson engineers saw the potential for filtration technologies in other product categories, tackling airborne pollutants in washrooms, homes and commercial spaces. Dyson purification and hand drying technologies use fully-sealed HEPA filtration to ensure particles like bacteria, viruses, pollen and dust are removed from the airflow, projecting cleaner air back into the room. For those who demand an even more thorough clean, Dyson’s latest vacuum cleaners also offer HEPA filtration.

-

-

The activated carbon layer in Dyson purifiers captures gases including VOCs and NO2. But Formaldehyde remained a problem – it can off-gas from carbon filters. The solution: Dyson’s Selective Catalytic Oxidation (SCO) filter continuously destroys formaldehyde at a molecular level. With the same structure as the Cryptomelane mineral, the filter’s coating has billions of atom-sized tunnels are the optimal size and shape to react with the formaldehyde molecules, converting them into tiny amounts of water and CO2.

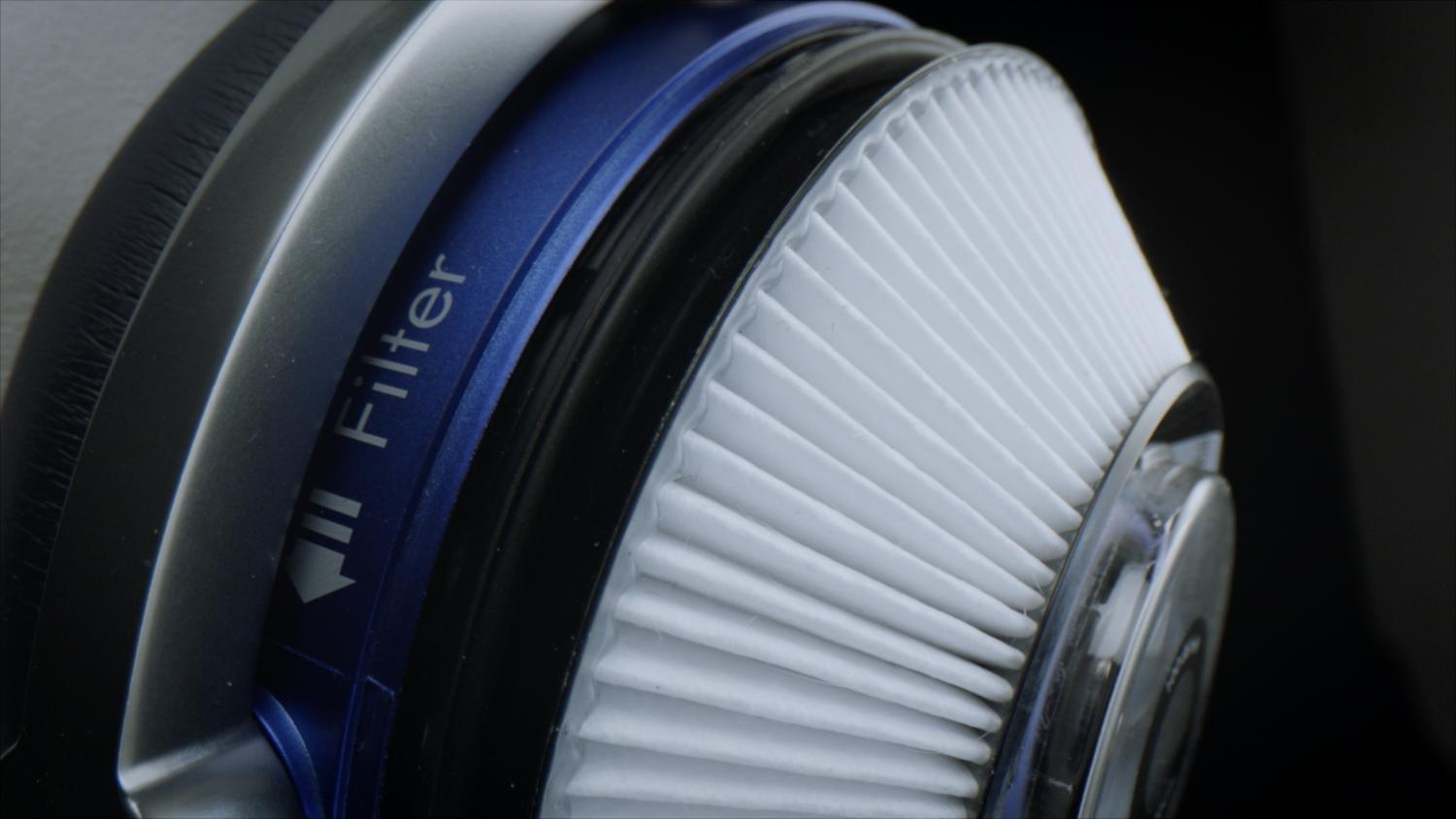

Finding a filter that fits

When developing the Dyson Zone™ noise-cancelling headphones, with specific size and weight requirements, our engineers already had a broad range of filtration experience but this brief posed new challenges. HEPA is highly efficient, but to remove realistic concentrations of city pollution, the filters would have needed to be very large and impossible to mount into a pair of headphones.

-

PTFE, another conventional filter media, was also investigated. FLIT boxes were an invention of Dyson’s Research team. These rigs allowed the engineers to better understand the use of PTFE in an outdoor environment. Each test looked like a beehive and many were placed across Dyson’s Malmesbury campus, in London and China, exposing different filter media to the elements. This testing proved that once PTFE gets wet, less and less air can pass through the filter, damaging performance.

So the team looked to electrostatic filtration. Negatively charged electrostatic filter media attracts and captures ultrafine particles including pollutants like allergens, or particles from brake dust, industry combustion and construction. It is also smaller in profile, removing the need for extremely large filters, but maintaining the high standard of purification required to capture city pollution.

Electrostatic filters, together with a potassium-enriched carbon layer which captures city gas pollutants like NO2 and SO2, ensure the Dyson Zone™ noise-cancelling headphones can tackle both indoor and outdoor pollutants.

-

Press Contacts

-

Press Office

Email: press.office@dyson.com

-