Let's get your machine working

Dyson Outsize Absolute

Let's get your machine working

Dyson Outsize Absolute

-

-

Troubleshooting

-

Alerts

-

Battery alerts

-

Charging the battery

-

LEDs whilst charging

-

Issue resolved

-

No power

-

Replacement part required

-

Replacement part required

-

Replacement part required

-

No LEDs whilst charging

-

Inspect display

-

Replacement part required

-

Replacement part required

-

Blue flashing LEDs whilst charging

-

Blockage alert

-

Check for blockages

-

Select floor tool

-

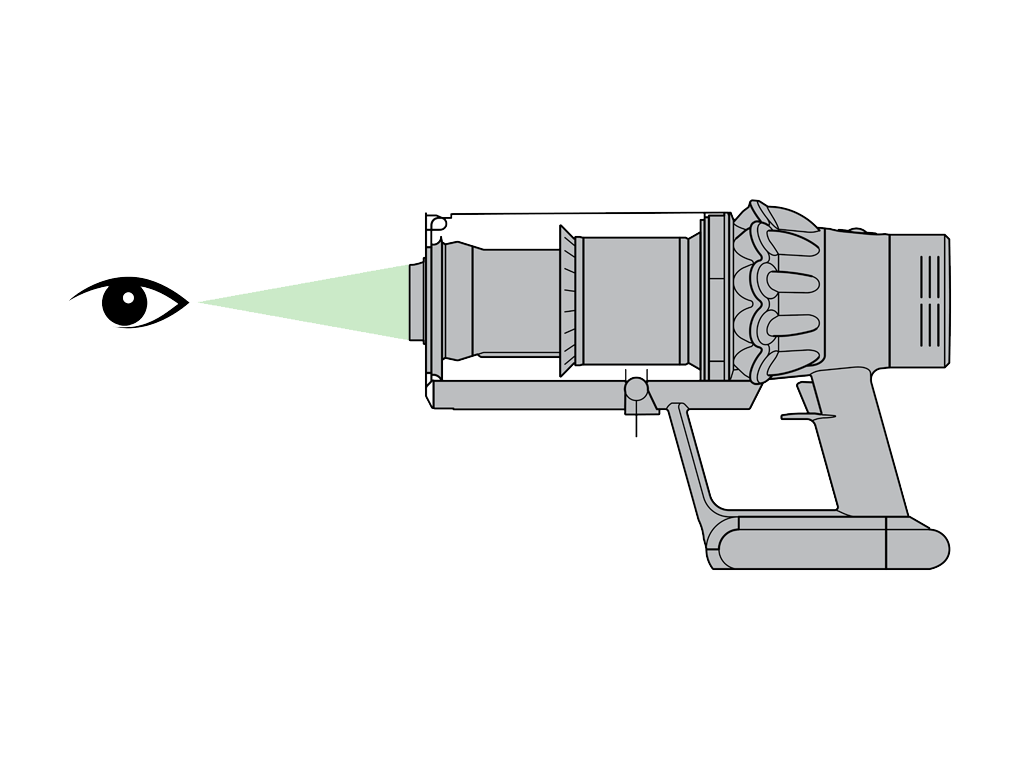

Laser Slim Fluffy™ cleaner head pulsing

-

Washing the brush bar

-

Check inlet

-

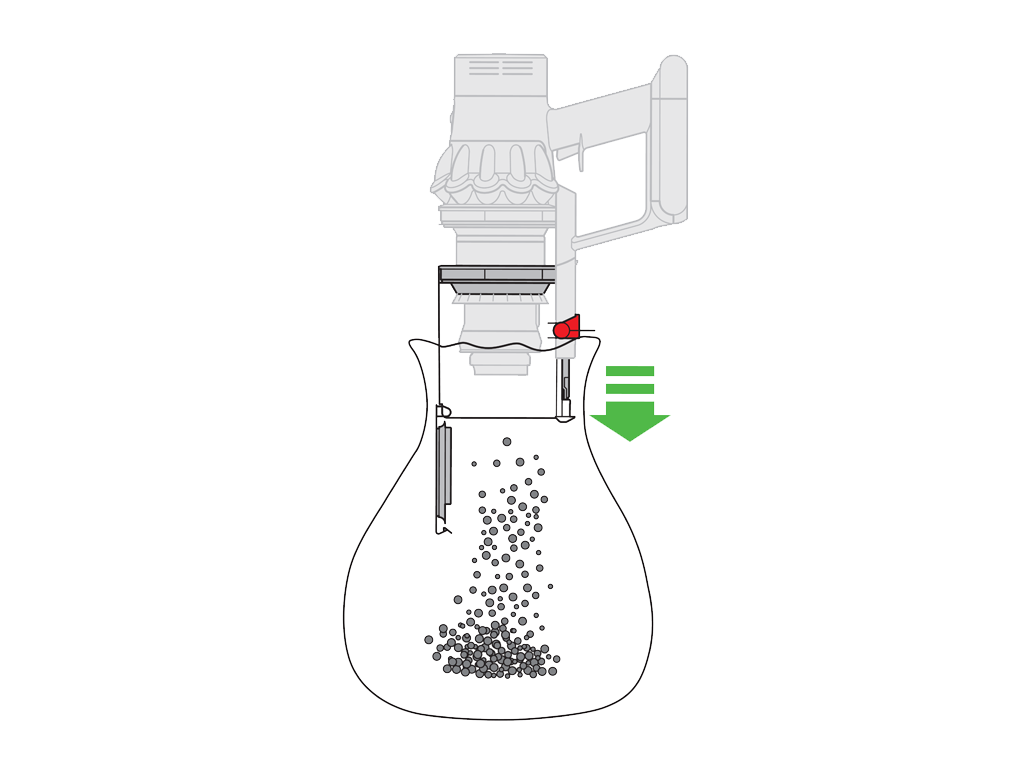

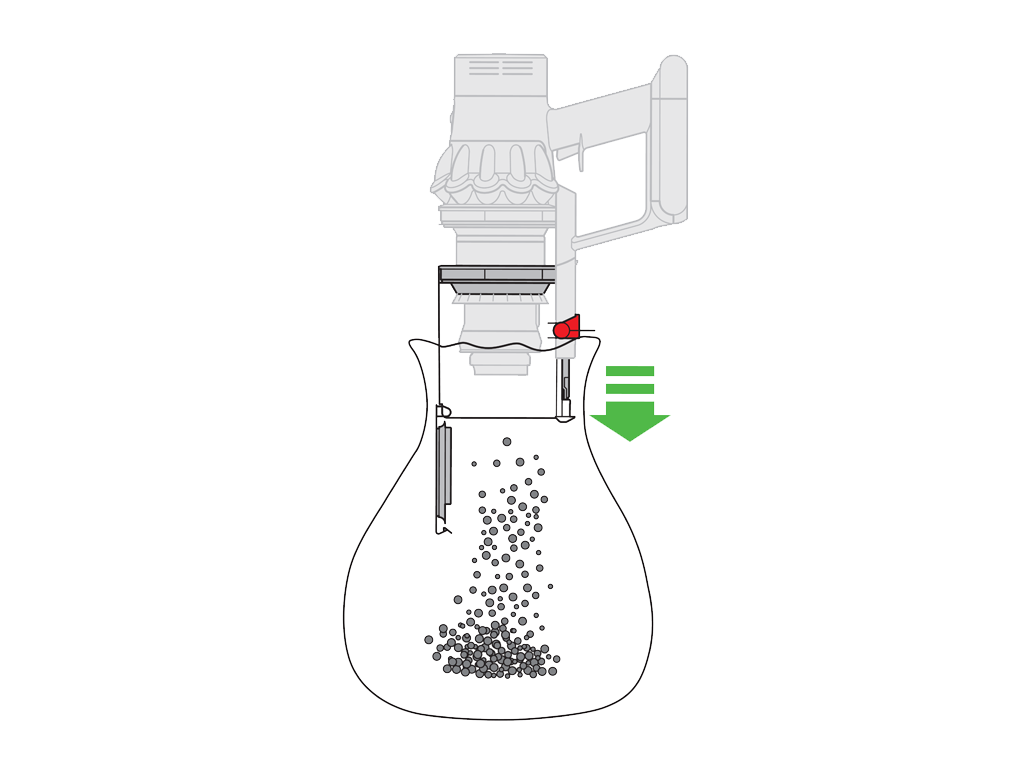

Clear the bin

-

Washing the filter - video

-

Washing the filter - step-by-step

-

Issue not resolved, please speak to our Customer Support Team

-

Accessory blocked

-

Direct drive cleaner head pulsing

-

High Torque cleaner head pulsating

-

QR Mini motorised head pulsing

-

Soft roller cleaner head pulsing

-

Washing the brush bars

-

Cutting out

-

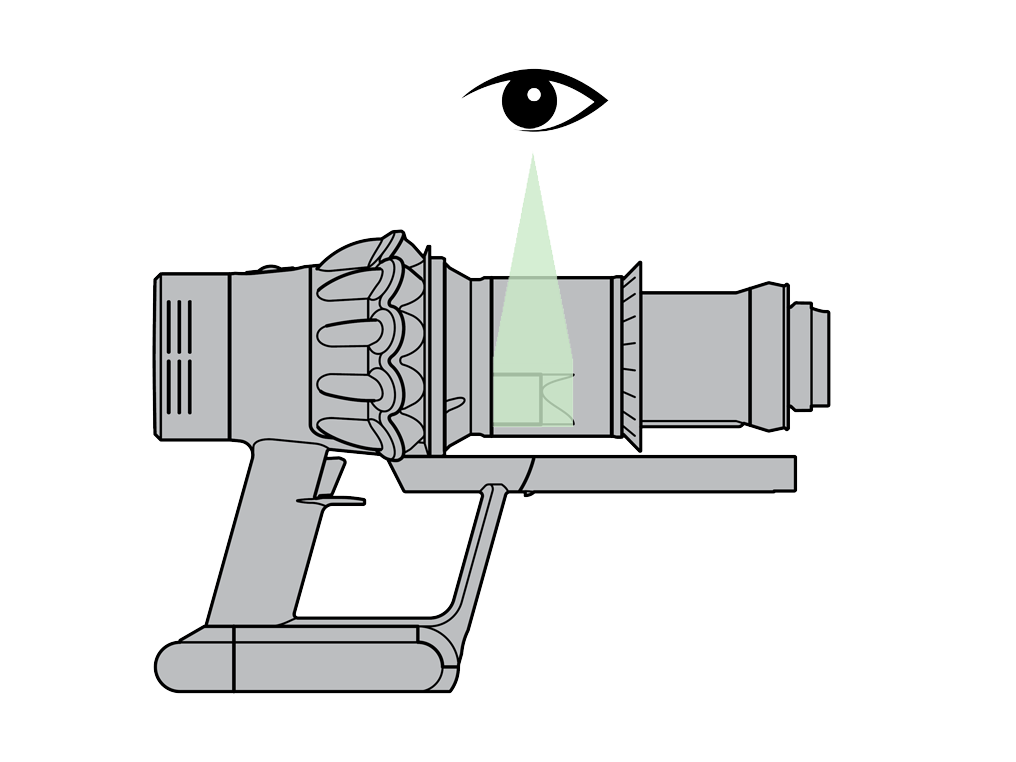

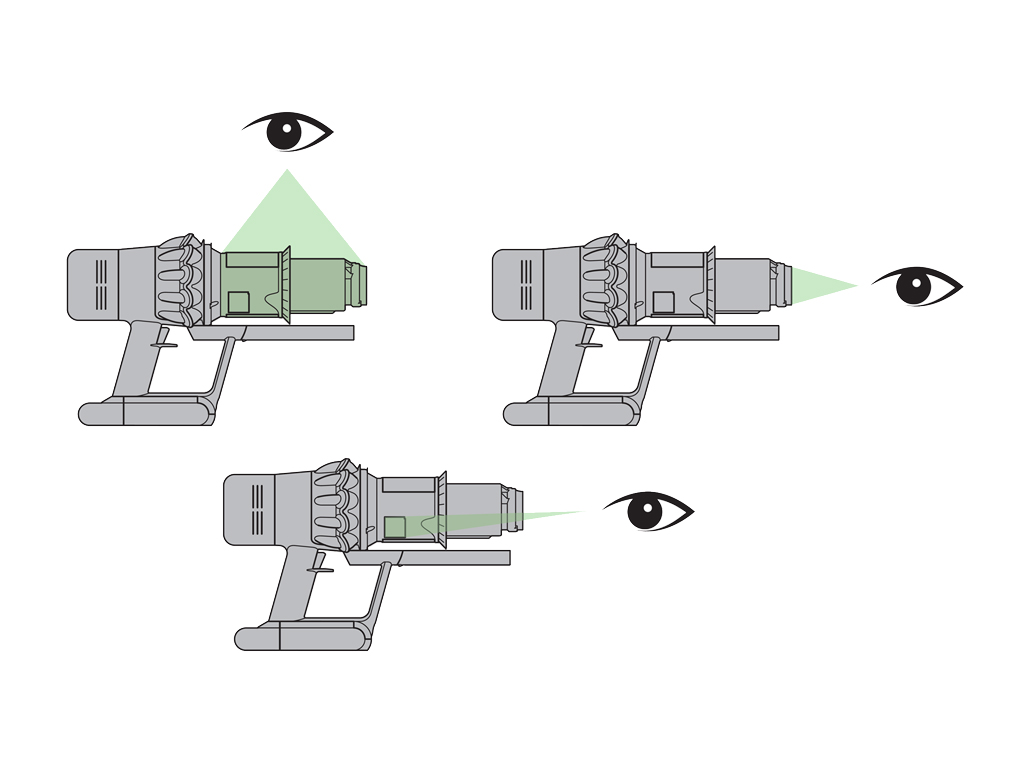

Diagnostic screen

-

Issue resolved

-

Unable to exit manually

-

Filter attachment alert

-

Wash the filter - video

-

Washing the filter - step-by-step

-

Replacement part required

-

Filter wash alert

-

Unusual noise

-

Grating or rattle

-

Test the machine

-

Check the bin inlet

-

Replacement part required

-

Pick up issues

-

Machine is not picking up well

-

Power or electrical issue

-

Cutting out

-

Run time

-

Run time inaccurate after removing from charge

-

Machine has no power

-

Machine overheating

-

Performance checks

-

Check for blockages

-

The machine has power but no display

-

LED showing

-

No power

-

No LED

-

Inspect display

-

Blue flashing LEDs whilst charging

-

The display shows run time remaining but the machine cut out

-

Charge the machine

-

High level of charge

-

Unusual smell

-

Damp or musty

-

Clean the bin

-

Washing the filter - video

-

Damp or musty smell

-

Washing the filter - step-by-step

-

Damp or musty smell

-

Damp or musty smell still present

-

Replacement part required

-

Issue not resolved, please speak to our Customer Support Team

-

Visible issue

-

The brush bar is not spinning on the floor tool

-

Laser Slim Fluffy™ cleaner head

-

Washing the brush bar

-

Replacement part required

-

Direct drive cleaner head

-

Replacement part required

-

High Torque cleaner head

-

Replacement part required

-

Quick-release Mini motorised head

-

Replacement part required

-

Soft roller cleaner head

-

Washing the brush bars

-

Replacement part required

-

Filter blocking frequently

-

Emptying the bin - video

-

Emptying the bin - step by step

-

Scratches or marks on the wand

-

Replacement part required

-

We're glad the problem's been solved.

Please let us know if there's anything else we can help you with.

The Dyson guarantee

'How to ' videos and tips

Exclusive owner benefits

Expert advice. 7 days a week.

Hassle-free repairs and replacement

You might need a replacement part.

It looks like the Main body and cyclone is not working. You can solve this by ordering a new one below.

Main body and cyclone

Part no. 970424-01

Replacement main body and cyclone for your Dyson cordless vacuum.

€79.95

Main body and cyclone

Part no. 970424-01

Replacement main body and cyclone for your Dyson cordless vacuum.

€79.95

€79.95

You might need a replacement part.

It looks like the Main body and cyclone is not working. You can solve this by ordering a new one below.

Main body and cyclone

Part no. 970424-01

Replacement main body and cyclone for your Dyson cordless vacuum.

€79.95

Main body and cyclone

Part no. 970424-01

Replacement main body and cyclone for your Dyson cordless vacuum.

€79.95

€79.95

You might need a replacement part.

It looks like the Main body and cyclone is not working. You can solve this by ordering a new one below.

Main body and cyclone

Part no. 970424-01

Replacement main body and cyclone for your Dyson cordless vacuum.

€79.95

Main body and cyclone

Part no. 970424-01

Replacement main body and cyclone for your Dyson cordless vacuum.

€79.95

€79.95

We need a little more information to help us solve your issue.

But our Customer Support Team will be able to solve your problem.

Please contact our customer service team on 01-475-7109, or directly on Live Chat through our Digital Assistant by clicking the purple icon at the bottom of the page. You can start a conversation with an Expert by clicking the agent icon at the bottom left of the chat window.

We need a little more information to help us solve your issue.

But our Customer Support Team will be able to solve your problem.

Please contact our customer service team on 01-475-7109, or directly on Live Chat through our Digital Assistant by clicking the purple icon at the bottom of the page. You can start a conversation with an Expert by clicking the agent icon at the bottom left of the chat window.

We need a little more information to help us solve your issue.

Please contact our customer service team on 01-475-7109, or directly on Live Chat through our Digital Assistant by clicking the purple icon at the bottom of the page. You can start a conversation with an Expert by clicking the agent icon at the bottom left of the chat window.

We're glad the problem's been solved.

Please let us know if there's anything else we can help you with.

The Dyson guarantee

'How to ' videos and tips

Exclusive owner benefits

Expert advice. 7 days a week.

Hassle-free repairs and replacement

We need a little more information to help us solve your issue.

But our Customer Support Team will be able to solve your problem.

Please contact our customer service team on 01-475-7109, or directly on Live Chat through our Digital Assistant by clicking the purple icon at the bottom of the page. You can start a conversation with an Expert by clicking the agent icon at the bottom left of the chat window.

You might need a replacement part.

It looks like the Bin is not working. You can solve this by ordering a new one below.

Bin

Part no. 970423-01

Replacement bin for your Dyson cordless vacuum.

€39.36

Bin

Part no. 970423-01

Replacement bin for your Dyson cordless vacuum.

€39.36

€39.36

We need a little more information to help us solve your issue.

Please contact our customer service team on 01-475-7109, or directly on Live Chat through our Digital Assistant by clicking the purple icon at the bottom of the page. You can start a conversation with an Expert by clicking the agent icon at the bottom left of the chat window.

We need a little more information to help us solve your issue.

Please contact our customer service team on 01-475-7109, or directly on Live Chat through our Digital Assistant by clicking the purple icon at the bottom of the page. You can start a conversation with an Expert by clicking the agent icon at the bottom left of the chat window.

We need a little more information to help us solve your issue.

But our Customer Support Team will be able to solve your problem.

Please contact our customer service team on 01-475-7109, or directly on Live Chat through our Digital Assistant by clicking the purple icon at the bottom of the page. You can start a conversation with an Expert by clicking the agent icon at the bottom left of the chat window.

You might need a replacement part.

You might need a replacement part.

It looks like the High Torque XL cleaner head is not working. You can solve this by ordering a new one below.

High Torque XL cleaner head

Part no. 970426-01

Full-size cleaner head with Dynamic Load Sensor (DLS) technology. Intelligently adapts suction and run time across all floor types. Covers more of your home faster.

€79.95

High Torque XL cleaner head

Part no. 970426-01

Full-size cleaner head with Dynamic Load Sensor (DLS) technology. Intelligently adapts suction and run time across all floor types. Covers more of your home faster.

€79.95

We need a little more information to help us solve your issue.

But our Customer Support Team will be able to solve your problem.

Please contact our customer service team on 01-475-7109, or directly on Live Chat through our Digital Assistant by clicking the purple icon at the bottom of the page. You can start a conversation with an Expert by clicking the agent icon at the bottom left of the chat window.

We need a little more information to help us solve your issue.

But our Customer Support Team will be able to solve your problem.

Please contact our customer service team on 01-475-7109, or directly on Live Chat through our Digital Assistant by clicking the purple icon at the bottom of the page. You can start a conversation with an Expert by clicking the agent icon at the bottom left of the chat window.

You might need a replacement part.

It looks like the Wand - Red is not working. You can solve this by ordering a new one below.

Wand - Red

Part no. 970481-03

Replacement red wand for your Dyson cordless vacuum.

€33.82

Wand - Red

Part no. 970481-03

Replacement red wand for your Dyson cordless vacuum.

€33.82

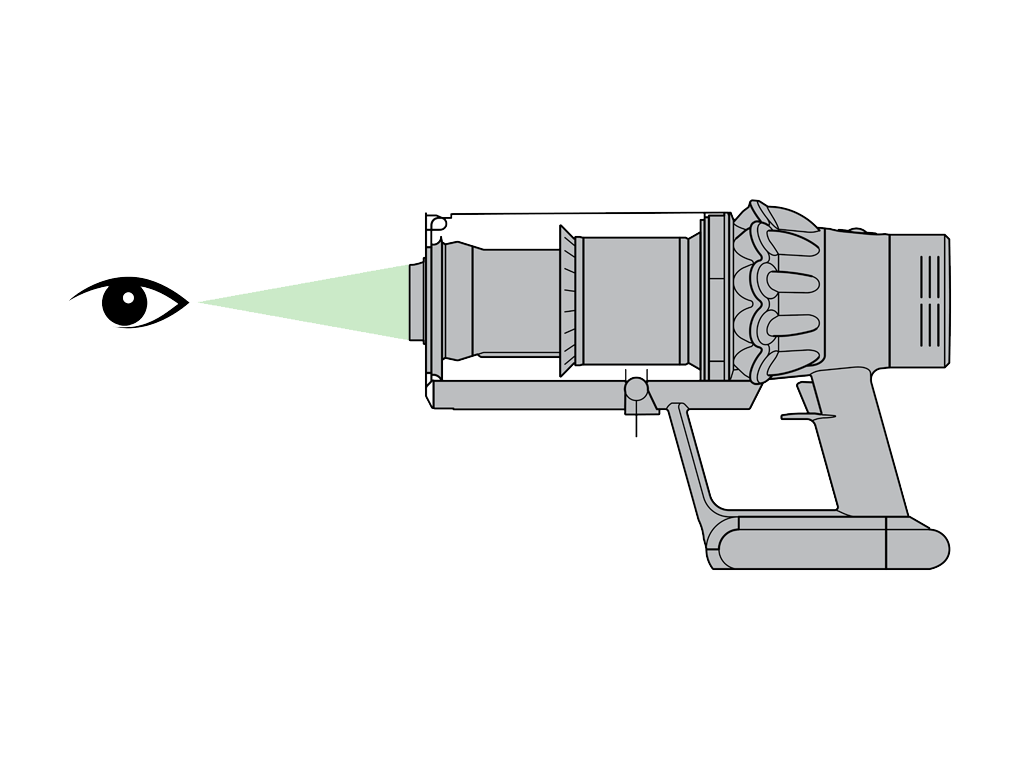

Unless prompted to do so, do not press the trigger when checking any part of the machine. Operating the machine while it is partially dismantled could result in personal injury.

Please select the appropriate option

Alerts

The screen will alert you when your machine needs your attention.

The alert will flash for approximately 5 seconds, proceeded by a playable graphic. Follow the instructions on screen to maintain performance.

Please select the appropriate option

Low battery

Fully charge the machine.

The machine should be charged with the battery attached to the machine.

Please select the next step

Please ensure the battery is charged to 100% after every use.

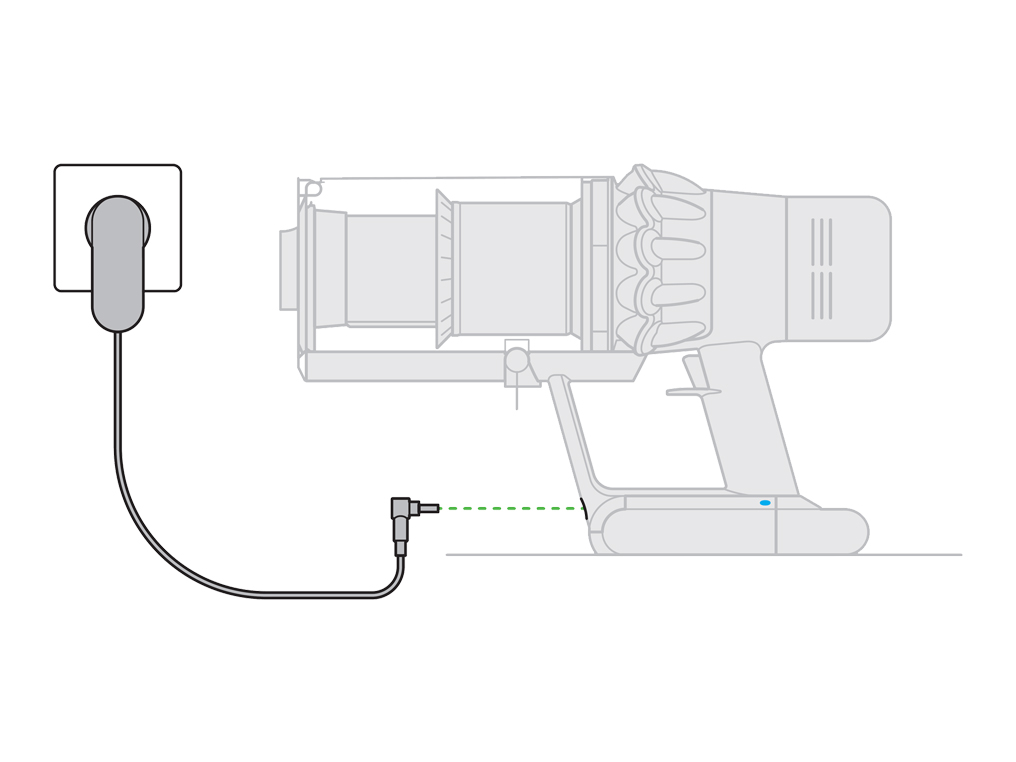

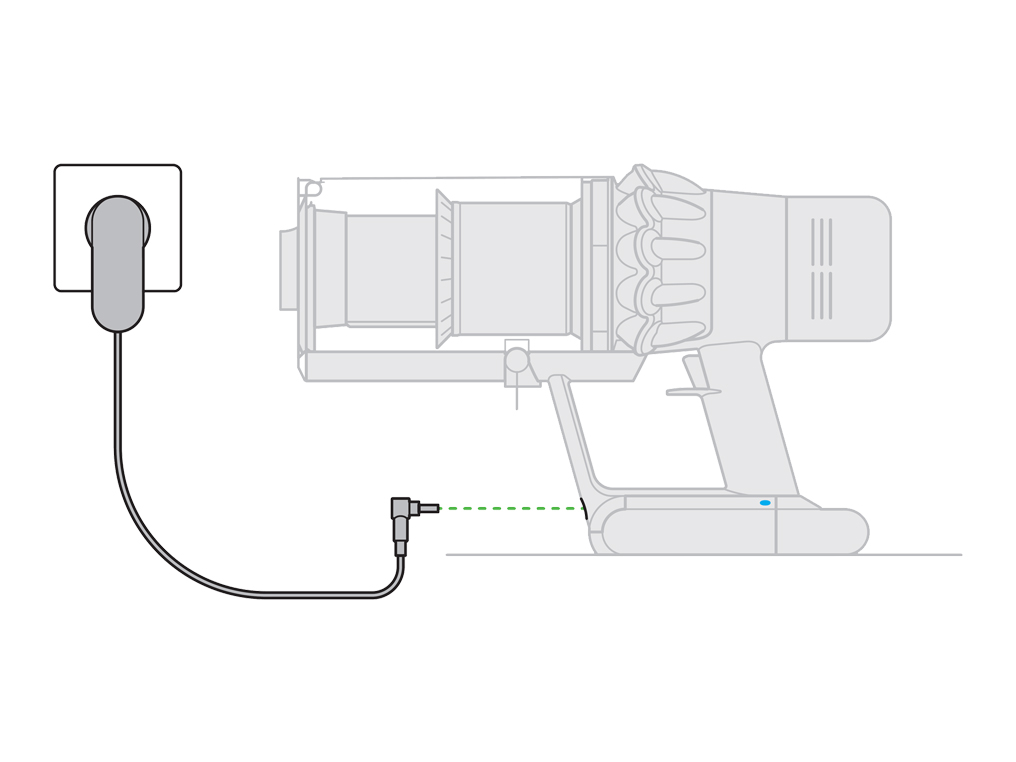

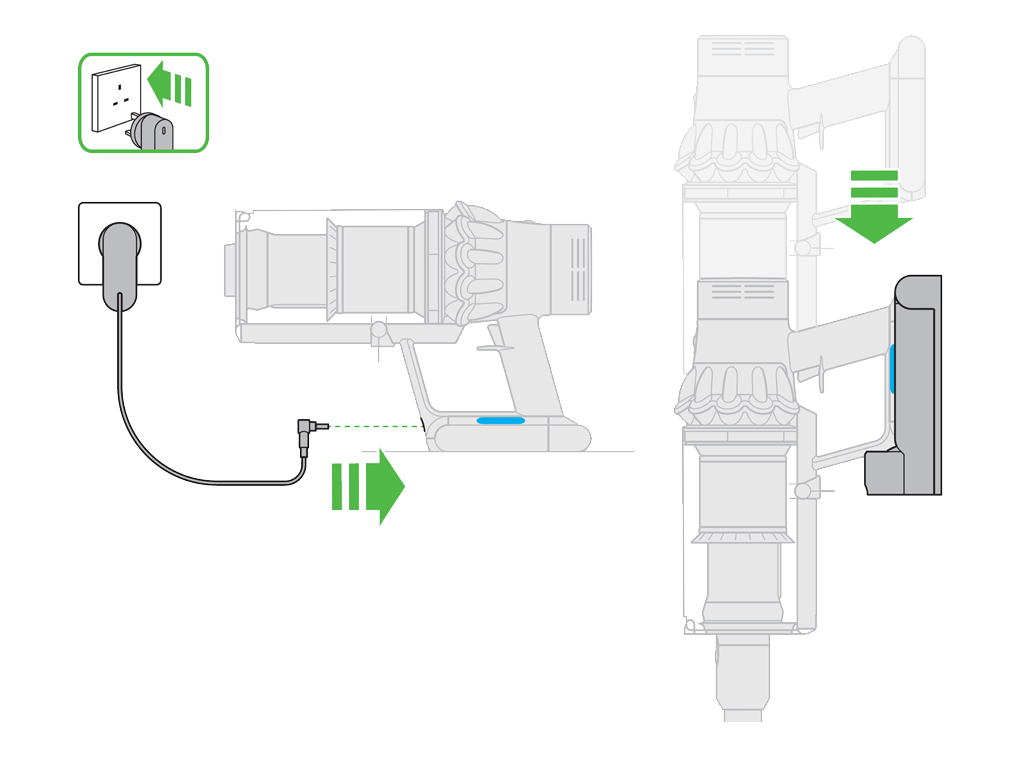

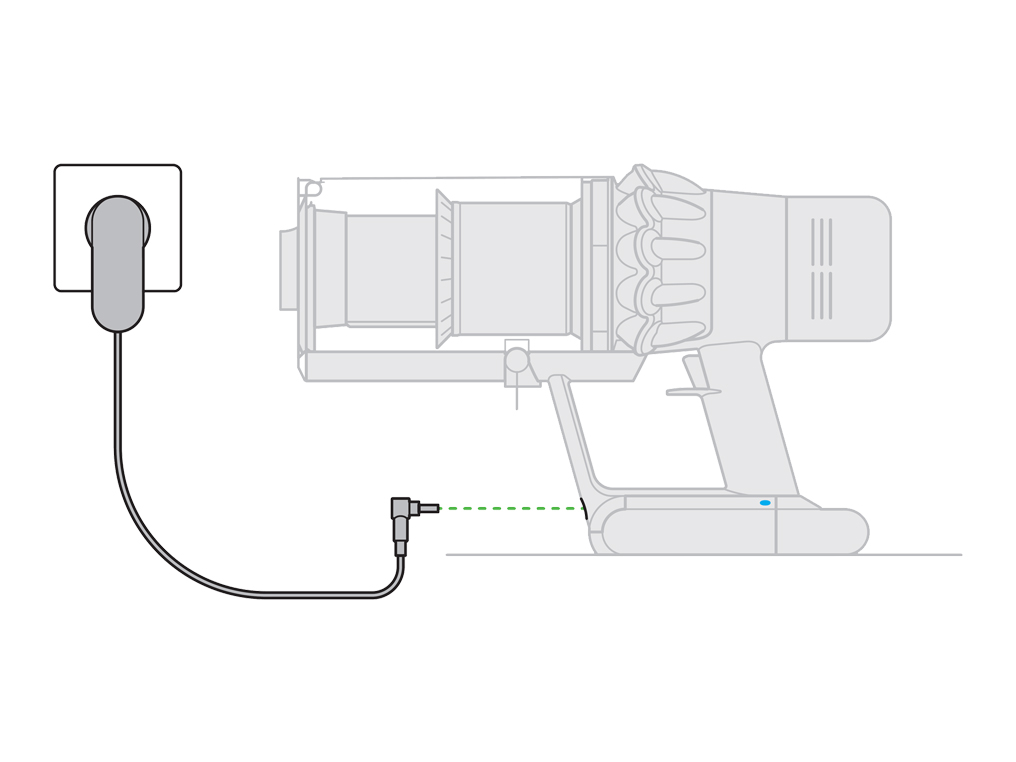

Charge the machine

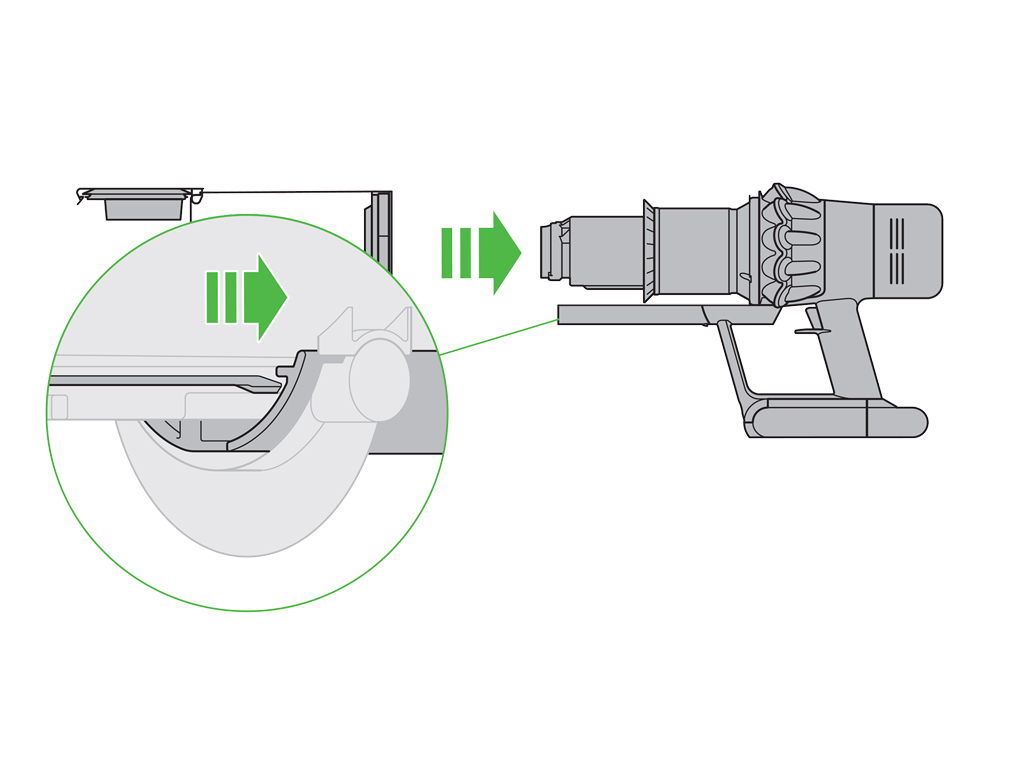

Connect to the charger either directly or in the docking station.

The blue LEDs on each side of the battery should light up.

Which lights are showing?

The blue LEDs – one on each side of the battery – will flash on and off during charging.

When the battery is charged, both LEDs will light for 5 seconds, then go out.

The screen will also show the battery charge level at 100%.

The machine can take up to 4.5 hours to fully charge.

Pull the trigger

Remove the charger from the machine and pull the trigger.

The LED lights should be on constantly when in use.

If the LED lights blink on/off for approximately 10 seconds when the trigger is pulled, please select 'LED lights blinking'.

Do the blue LED lights appear on either side of the battery?

Dock charging

If the machine is being charged through the docking station, please disconnect the charger and connect it directly into the machine.

Please check household electrics or use an alternative plug socket.

Remove the charger

Press and hold the trigger for 10 seconds.

The blue LEDs – one on each side of the battery – will flash on and off during charging.

When the battery is charged, both LEDs will light for 5 seconds, then go out.

The screen will also show the battery charge level at 100%.

The machine can take up to 4.5 hours to fully charge.

Automatic cut out

Large items may block the machine or tools. If any part becomes blocked or the filter needs washing, the machine may automatically cut out.

Motor is pulsating

This will happen after the motor pulses a number of times (i.e. switches on and off in quick succession) and the blockage indicator will light. Leave to cool down before looking for blockages.

Be careful not to pull the 'ON' trigger while looking for blockages. Operating the machine while it is partially dismantled could result in personal injury.

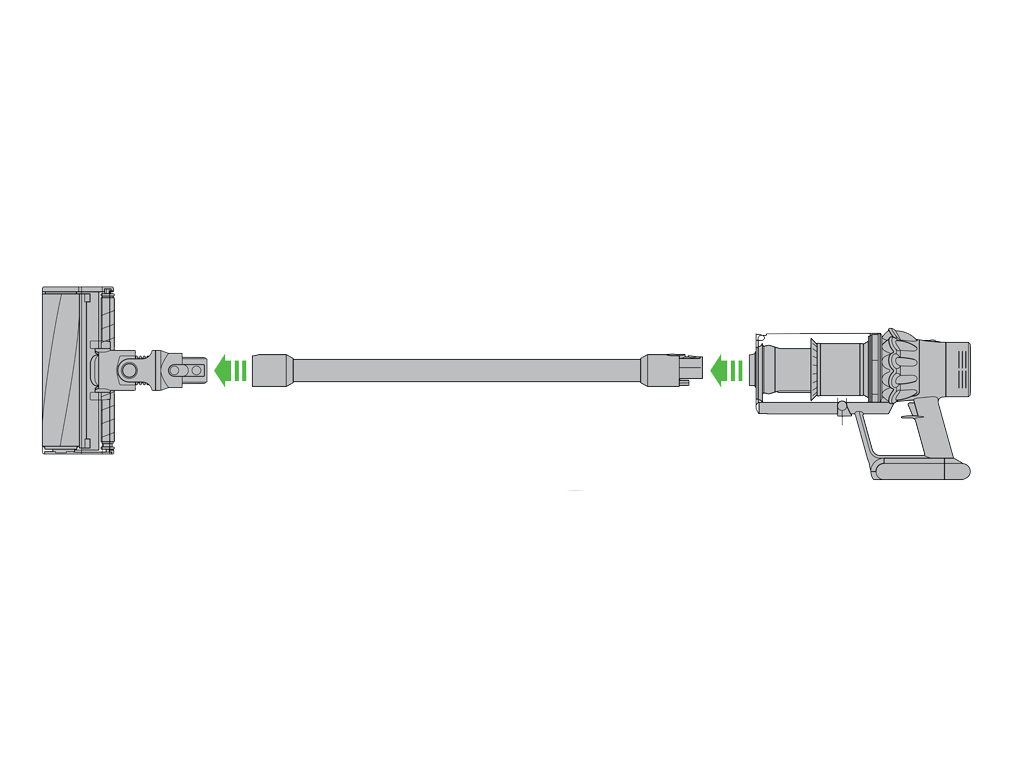

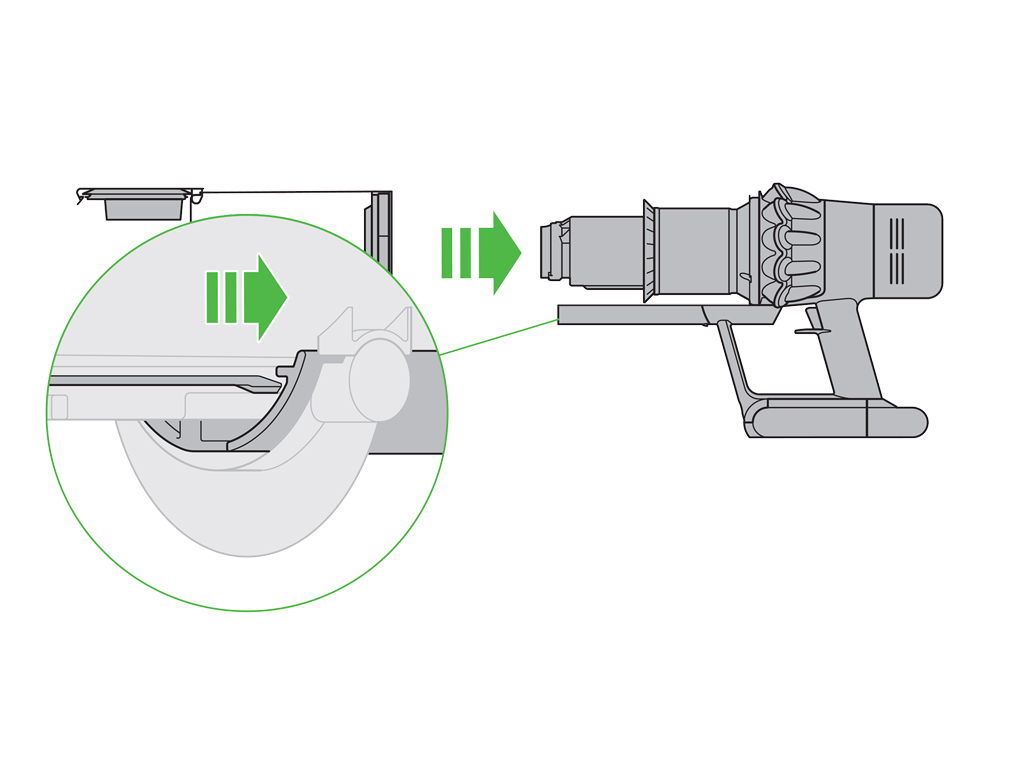

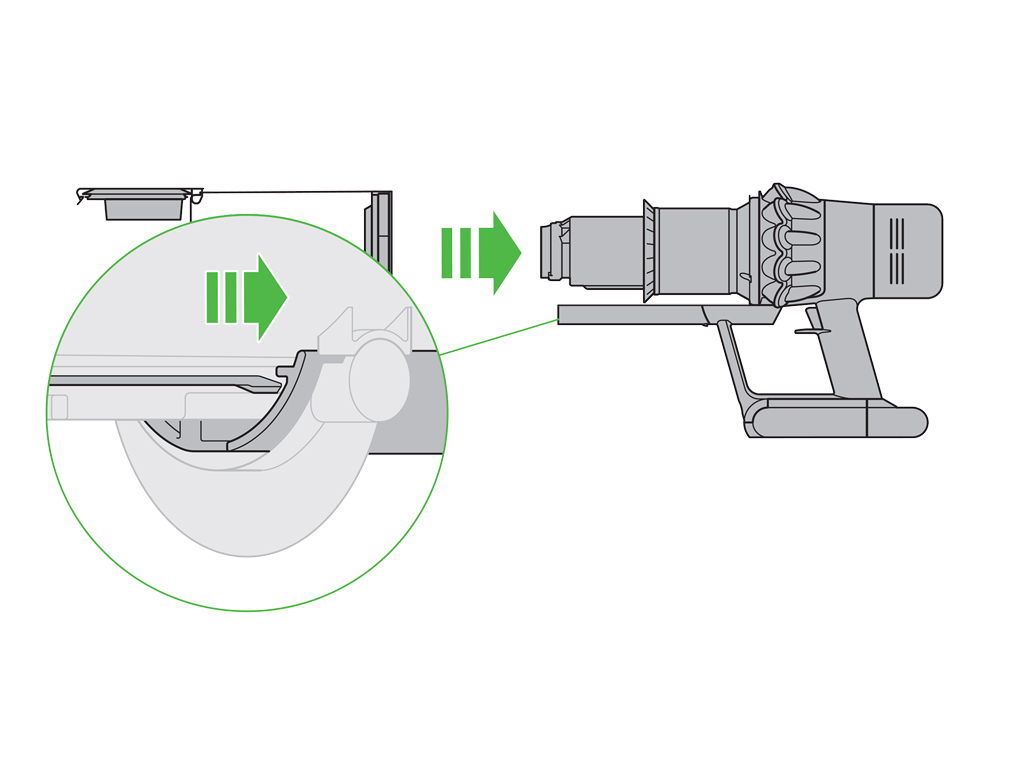

Remove the tools

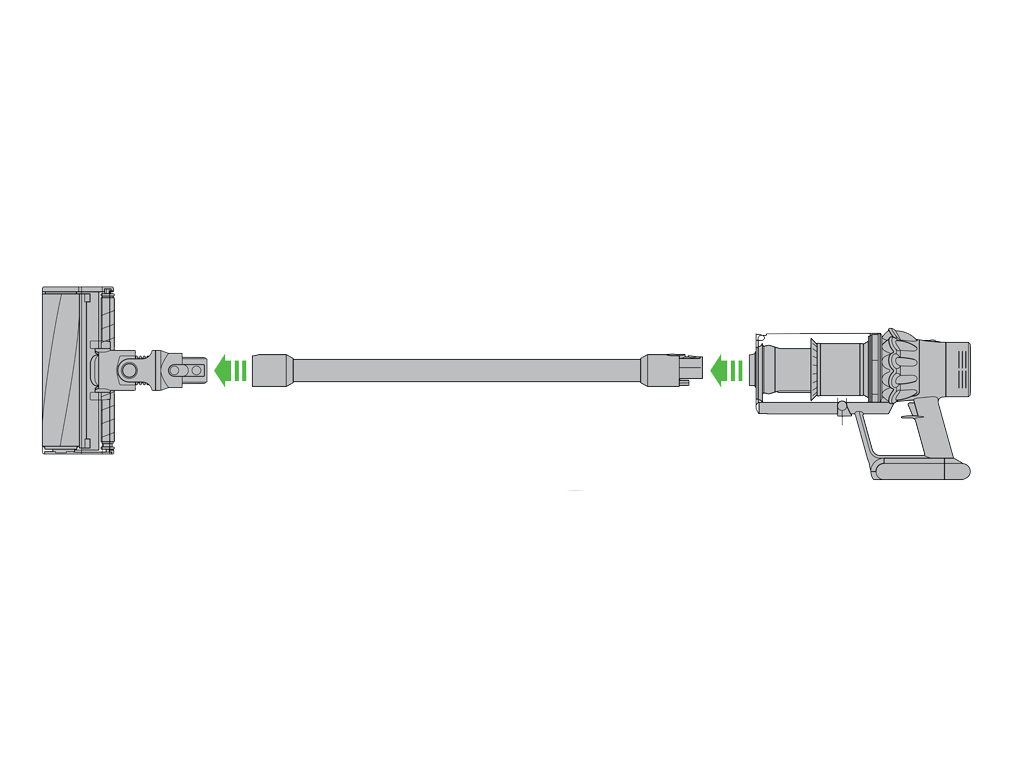

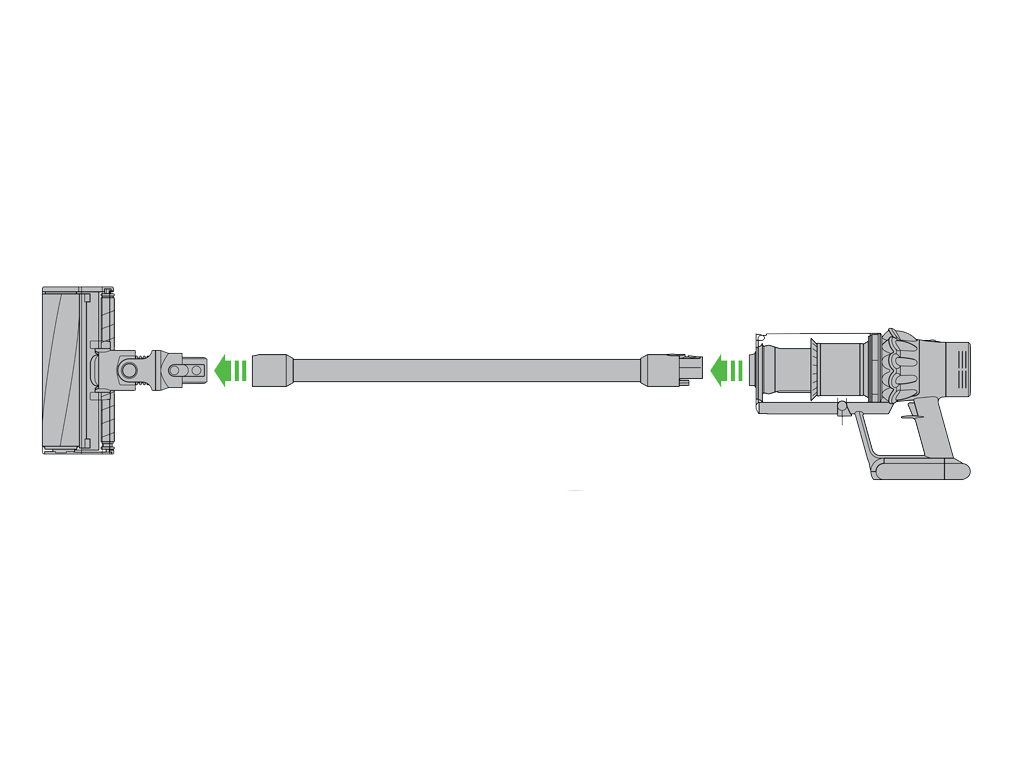

Remove all tools and accessories from the machine e.g. wand, cleaner head, crevice tool etc. Please ensure the bin is empty before continuing with any checks.

Press and hold the trigger for 10 seconds.

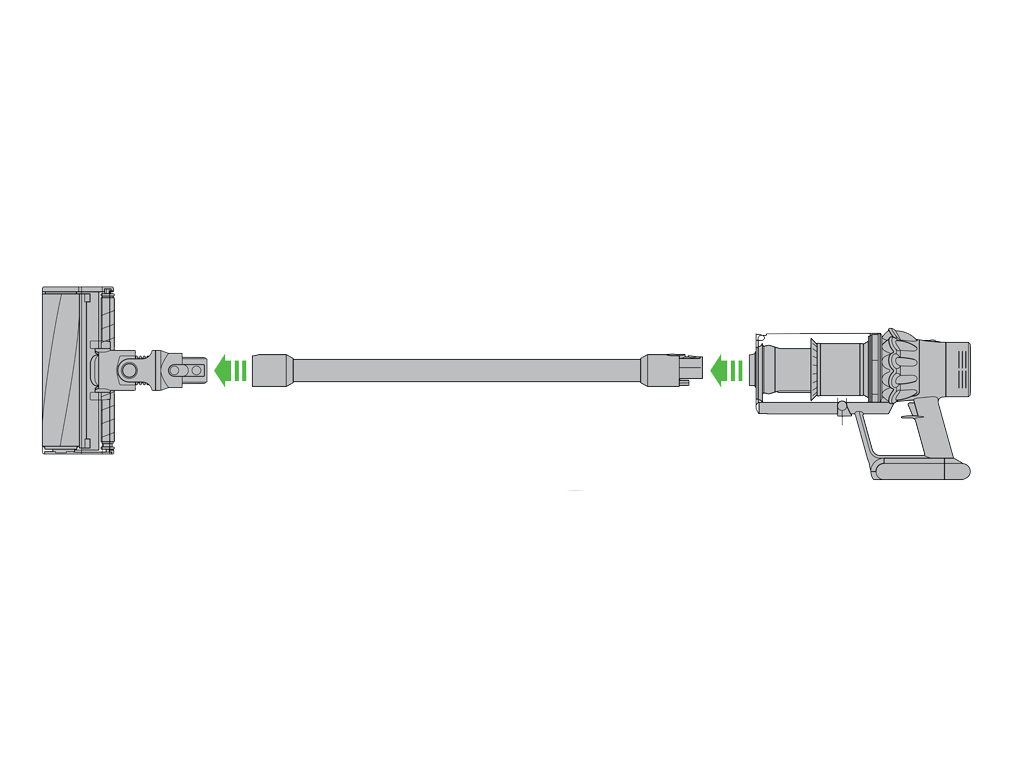

Check for blockages

Check both ends of the wand for blockages and remove as necessary.

Reattach the cleaner head, tool or accessory to the wand. Reattach the wand to the machine.

Press and hold the trigger for 10 seconds.

Which floor tool are you using?

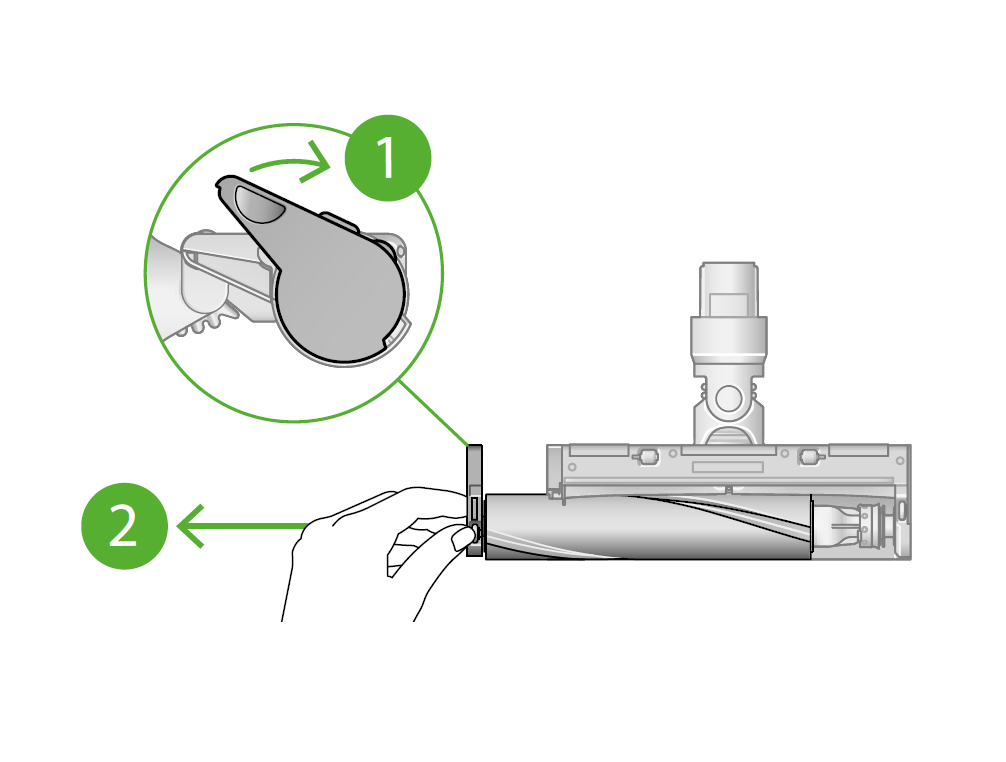

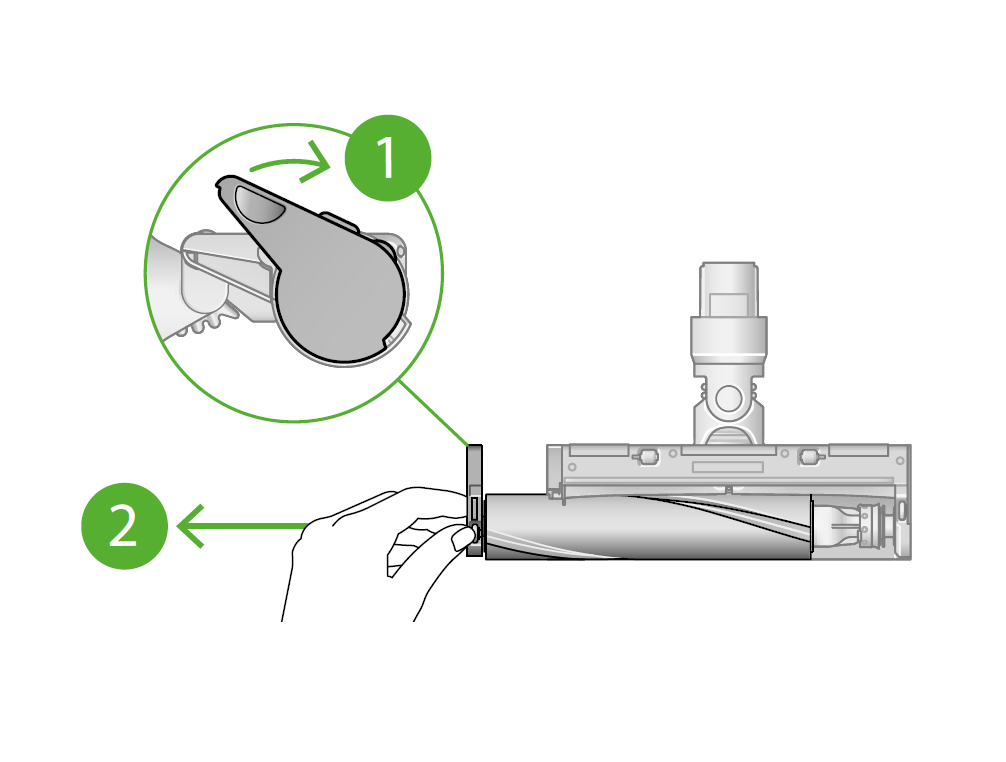

Remove any debris from the brush bar.

Slide the Brush bar back onto the Cleaner head, around the motor. The end cap should be in the open position as shown.

Push the end cap until it clips securely back into the closed position.

Has this resolved the problem?

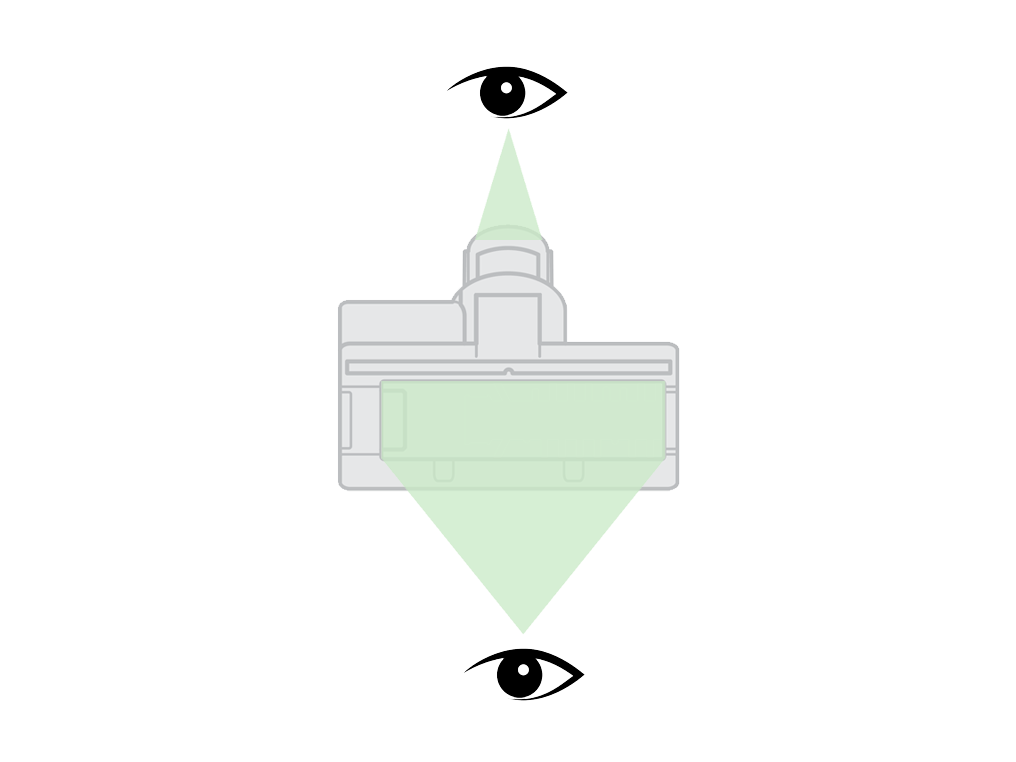

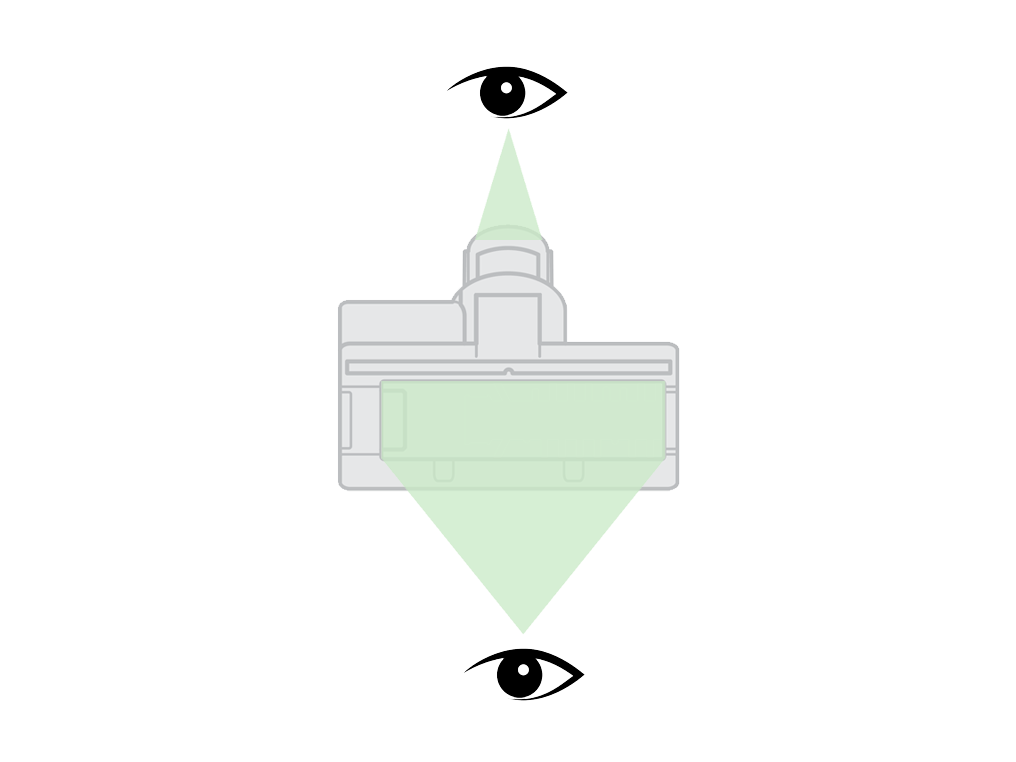

Turn the cleaner head upside down so the underside of the cleaner head is facing you.

Push the end cap upwards until it opens and pull the brush bar out of the cleaner head.

Remove the end cap from the brush bar. Do not wash the end cap.

Hold the brush bar under running water and gently rub to remove any lint or dirt.

Stand the brush bar upright as shown. Leave to dry completely for a minimum of 24 hours.

Reattach the end cap to your brush bar.

Slide the Brush bar back onto the Cleaner head, around the motor. The end cap should be in the open position as shown.

Push the end cap until it clips securely back into the closed position.

Check the bin inlet

Check the inlet at the front of the machine for any blockages and remove as necessary.

Check the shroud opening

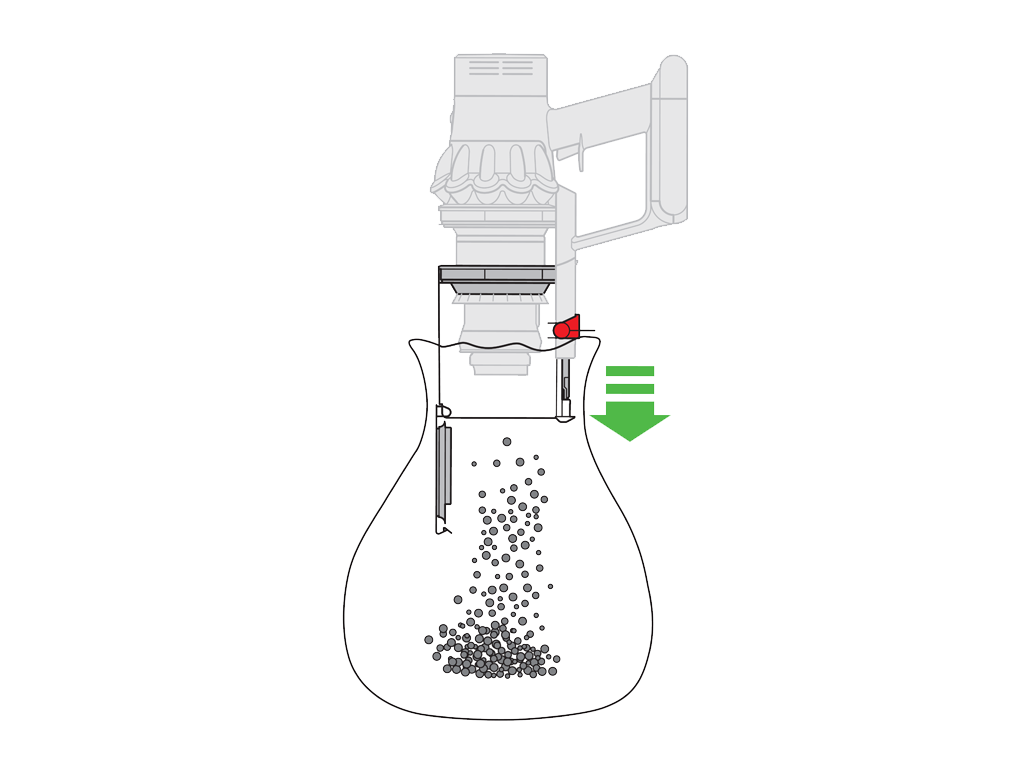

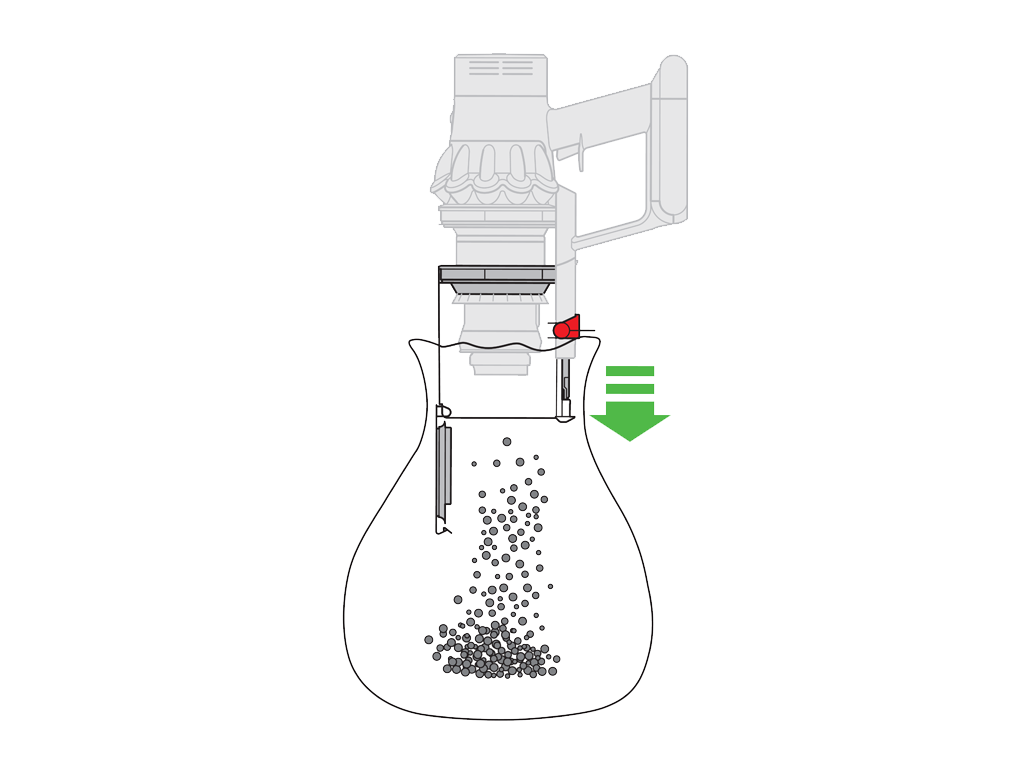

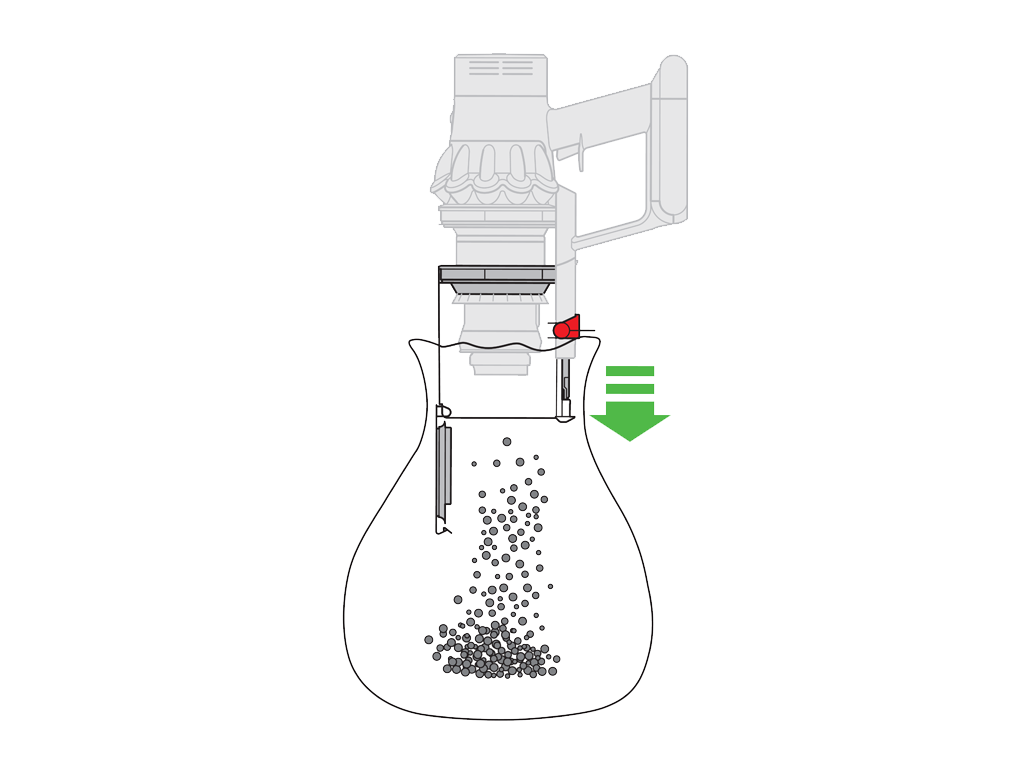

Hold the machine with the bin in a downwards position. Firmly push the red bin release button. The bin will slide down opening the bin base. The bin base will not open if the red button is not pushed down fully.

Check the opening on the cyclone shroud for any blockages. Remove as necessary.

Close the clear bin by pushing the bin base upwards until it clicks into place.

Press and hold the trigger for 10 seconds.

Remove the bin

Hold the machine with the bin in a downwards position. Firmly push the red bin release button. The bin will slide down opening the bin base. The bin base will not open if the red button is not pushed down fully.

Press the red button located on the bin runner to release the bin and slide the bin off the runner.

Gently tap the side of the cyclone over a bin. This will remove any fine dust clogged up in the cyclone. Using the combination tool, clean the shroud to remove any debris around the cyclone.

Check the cyclone for blockages and remove as necessary.

To refit the clear bin

Insert the spine into the bin runner.

Close the clear bin by pushing the bin base upwards until it clicks into place.

Attach the wand and cleaner head and test the machine.

This indicates the filter needs washing.

Please follow the steps in the video.

Find the text version of the step-by-step guide instead, under "Has this resolved the problem?"

Leave the filter to dry for a minimum of 24 hours in an environment with good airflow. Ensure that the filter is completely dry before reinserting it into the machine.

Press and hold the trigger for 10 seconds.

Has this resolved the problem?

Removing the filter

Remove the filter by turning it anticlockwise. Gently pull it away from the machine.

Gently tap the filter unit to remove any excess dust and debris before washing it.

Wash the filter in cold water only.

WARNING: Please do not use detergent, do not wash in a dishwasher or washing machine.

Wash the pleated paper element of the filter unit first; hold the filter unit under a cold water tap with the foam element downwards and run cold water over the pleated paper. Continue washing until the water runs clear.

Wash the foam element of the filter unit next; hold the filter unit under a cold water tap with the foam element downwards so that dirty water does not contaminate the pleated paper element. Run cold water over the inside and outside of the foam element and squeeze the foam gently to expel the dirt. Continue washing until the water runs clear.

Wash the outside of the filter unit. Then fill the unit with cold water, place your hands over the open ends and shake gently. Repeat washing the elements and outside of the filter unit until the water runs clear.

Gently shake the filter unit to remove any excess water and leave to drain with the foam element end facing up.

Drying

Leave the filter to dry for a minimum of 24 hours in an environment with good airflow. Ensure that the filter is completely dry before reinserting it into the machine.

Refit

Insert the filter back into the machine. Turn the filter clockwise until it clicks into place.

The filter may need to be washed more frequently if you are vacuuming a lot of fine dust, or if the machine is predominantly being used in Boost mode.

Check for blockages

With the accessory removed from the machine, check both ends for blockages and remove as necessary.

Refit the accessory back onto the machine.

Press and hold the trigger for 10 seconds.

Clear the floor tool

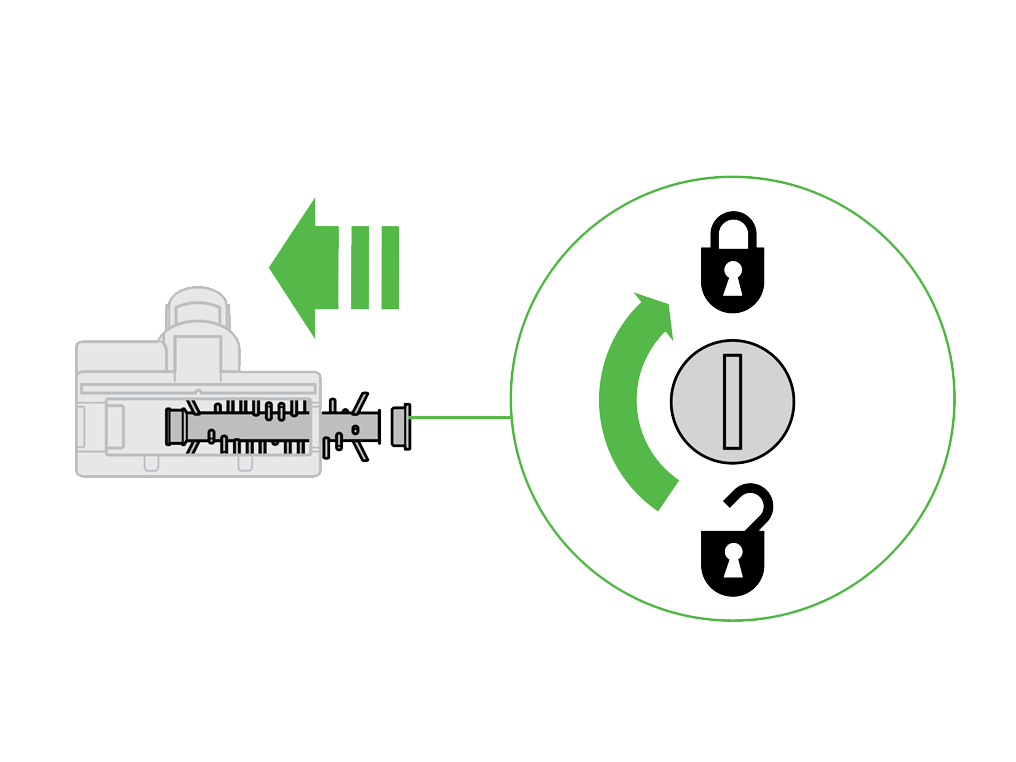

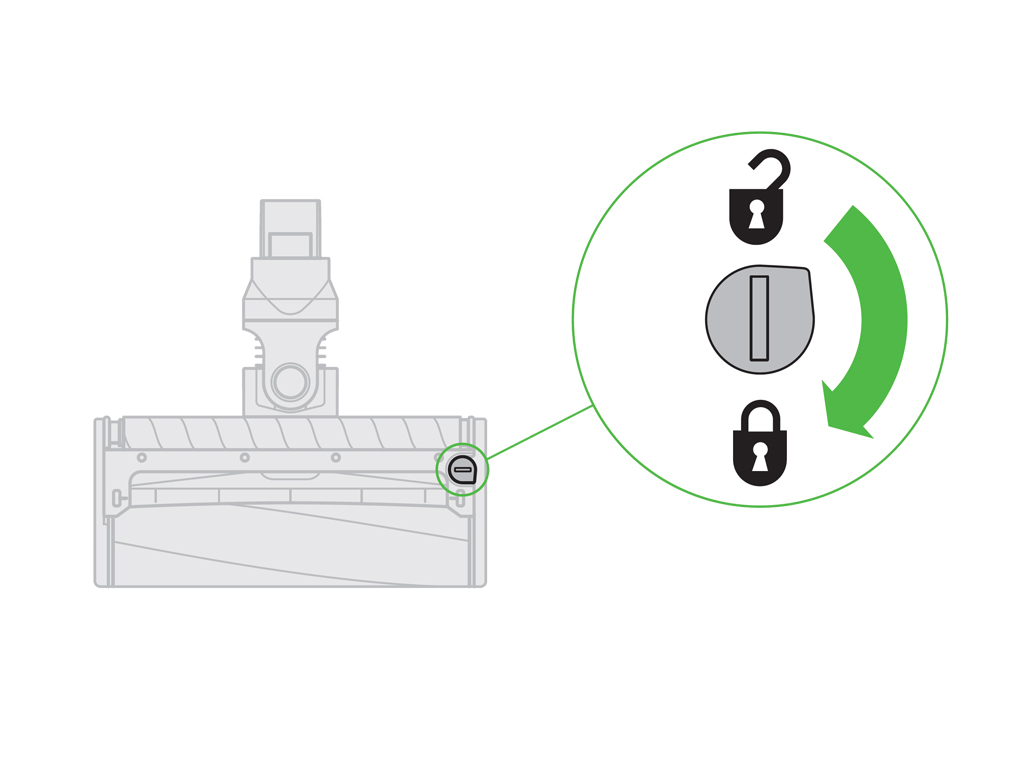

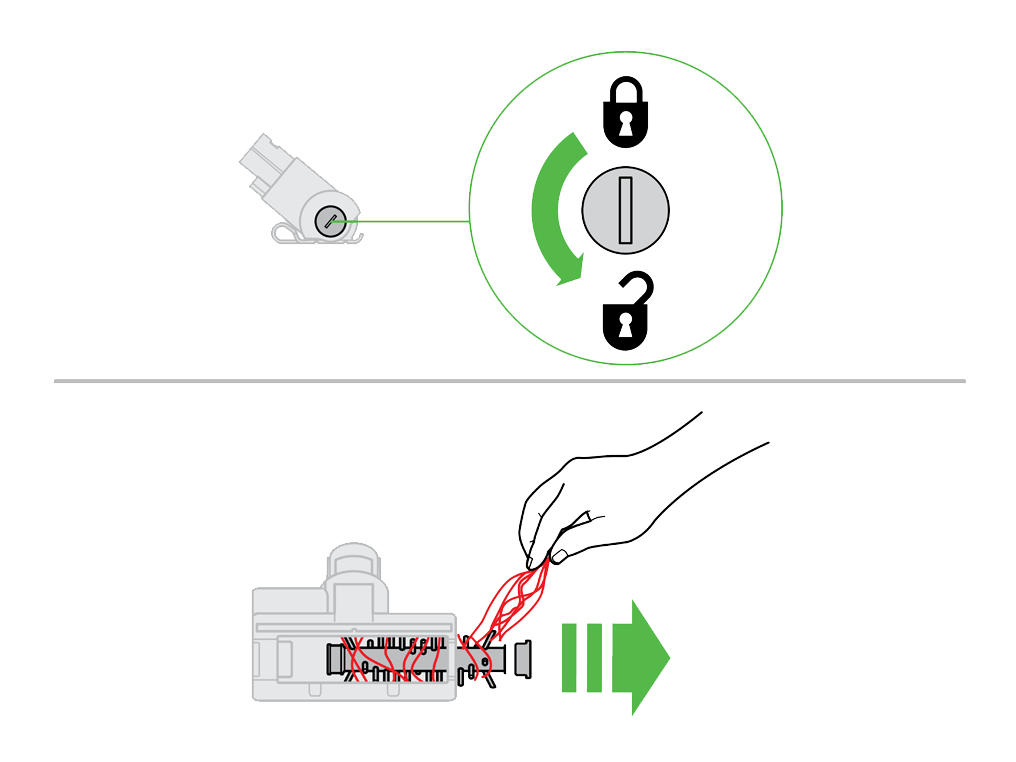

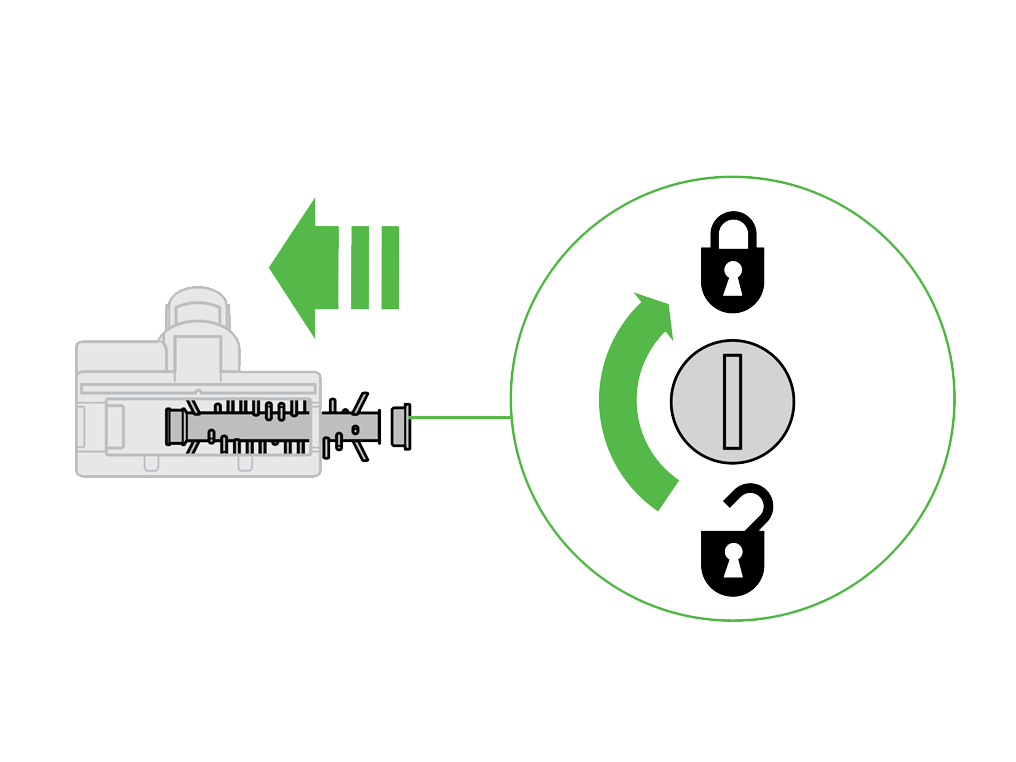

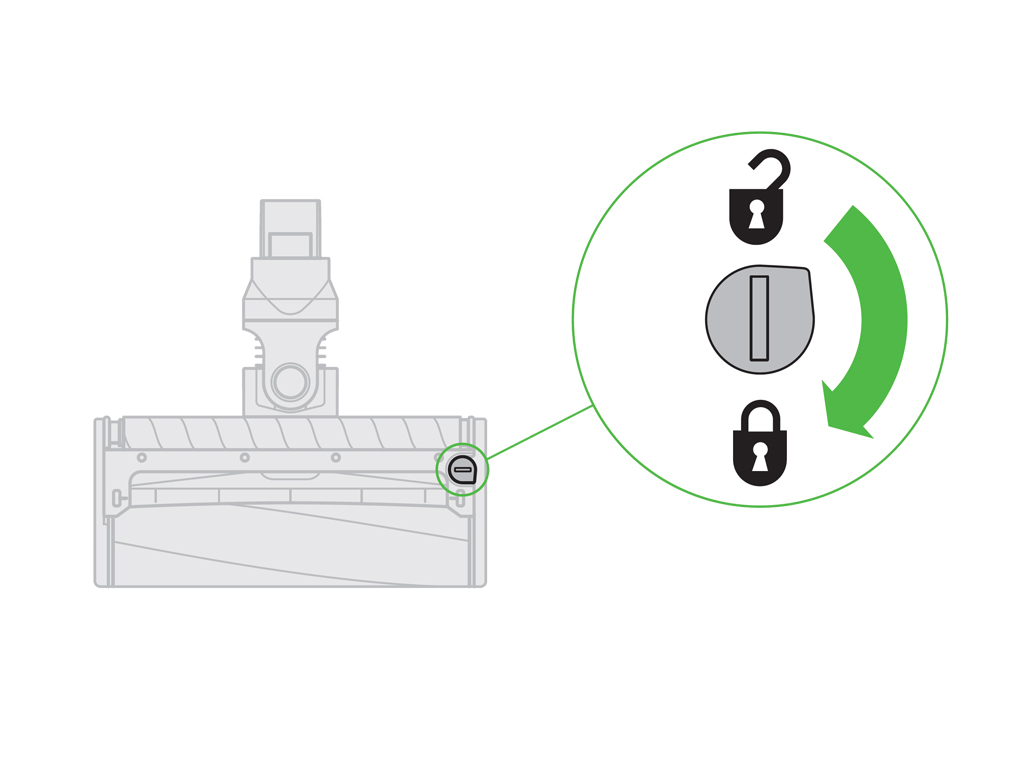

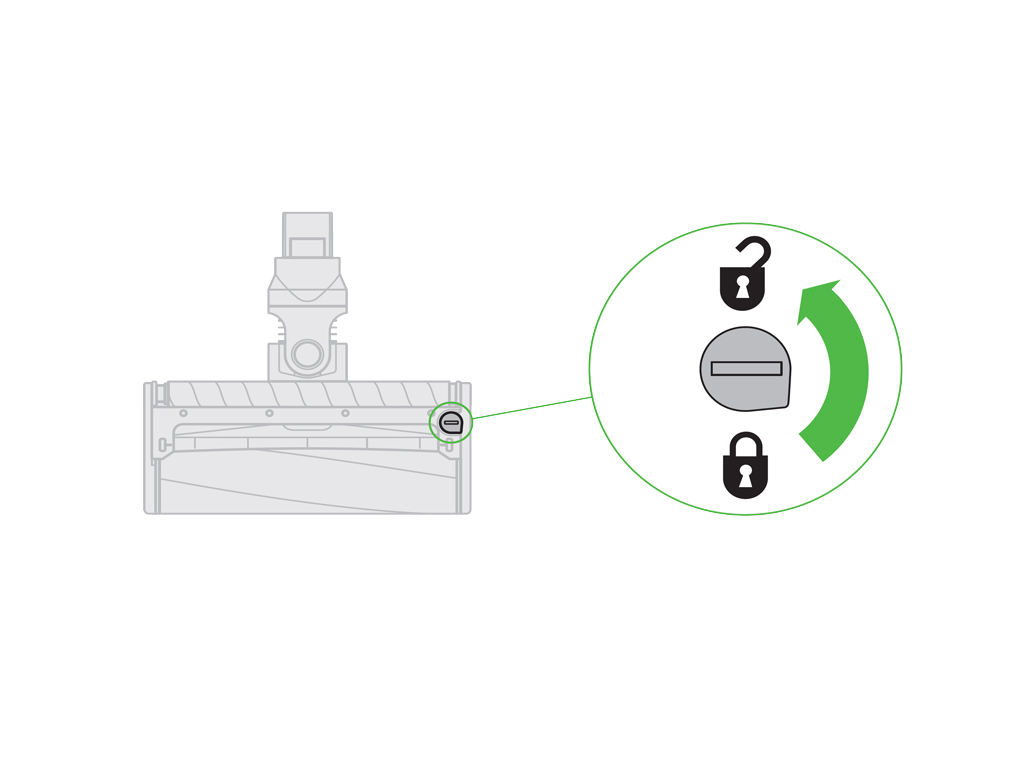

On the side of the cleaner head, locate the end cap. Using a coin, turn the end cap anticlockwise a quarter of the way to remove it.

Note: There should be a small padlock icon along with directional arrows to help you unlock the end cap.

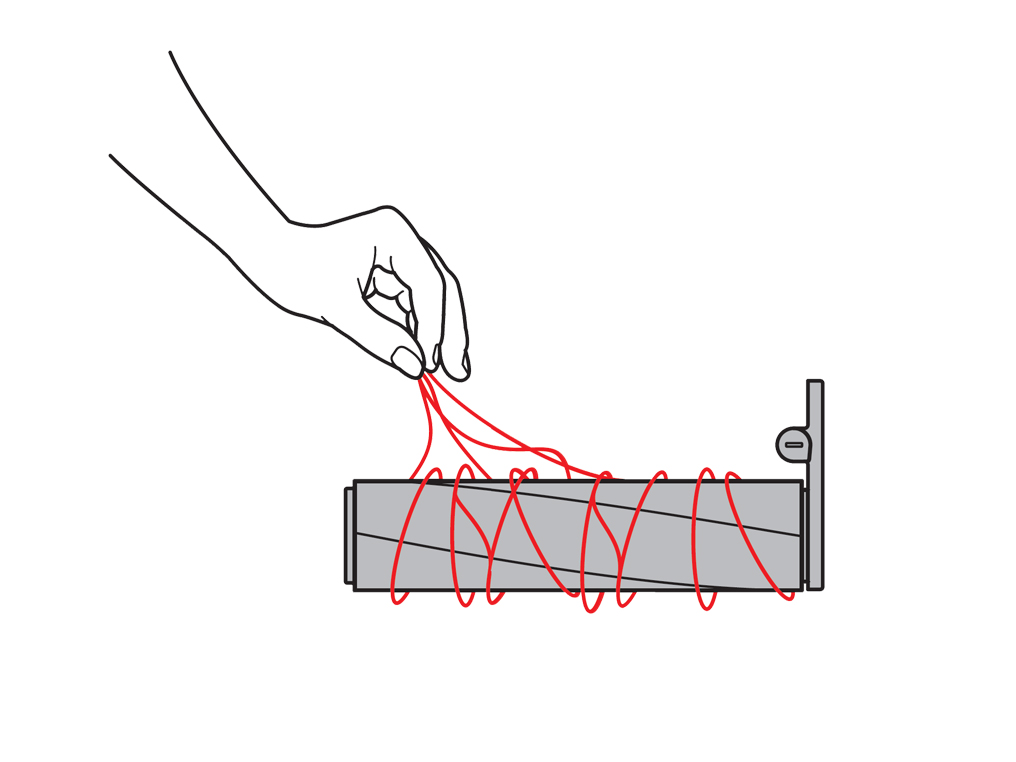

Remove the brush bar from the Direct drive cleaner head and clear away any hair or fibres. Check the neck of the cleaner head (where the cleaner head connects to the wand) for any blockages. Ensure there is no build-up of dust or debris in the small crevice between where the brush bar sits and the neck of the cleaner head.

The brush bar, now clear of any debris, can be reinserted into the cleaner head. Securely fasten the end cap.

Clear the floor tool

On the side of the cleaner head, locate the end cap. Using a coin, turn the end cap anticlockwise a quarter of the way to remove it.

Note: There should be a small padlock icon along with directional arrows to help you unlock the end cap.

Remove the brush bar from the High Torque cleaner head and clear away any hair or fibres. Check the neck of the cleaner head (where the cleaner head connects to the wand) for any blockages. Ensure there is no build-up of dust or debris in the small crevice between where the brush bar sits and the neck of the cleaner head.

The brush bar, now clear of any debris, can be reinserted into the cleaner head. Securely fasten the end cap.

Place the cleaner head onto the bin, change the suction control slider to the positive position and test the machine.

Switch the suction control slider to the negative setting and continue testing.

Clear the floor tool

On the side of the Mini motorised head, locate the end cap. Using a coin, turn the end cap anticlockwise a quarter of the way to remove it.

Note: There should be a small padlock icon along with directional arrows to help you unlock the end cap.

Remove the brush bar from the Quick-release Mini motorised head and clear away any hair or fibres. Check the neck of the cleaner head (where the cleaner head connects to the wand) for any blockages. Ensure there is no build-up of dust or debris in the small crevice between where the brush bar sits and the neck of the cleaner head.

The brush bar, now clear of any debris, can be reinserted into the cleaner head. Securely fasten the end cap.

Clear the floor tool

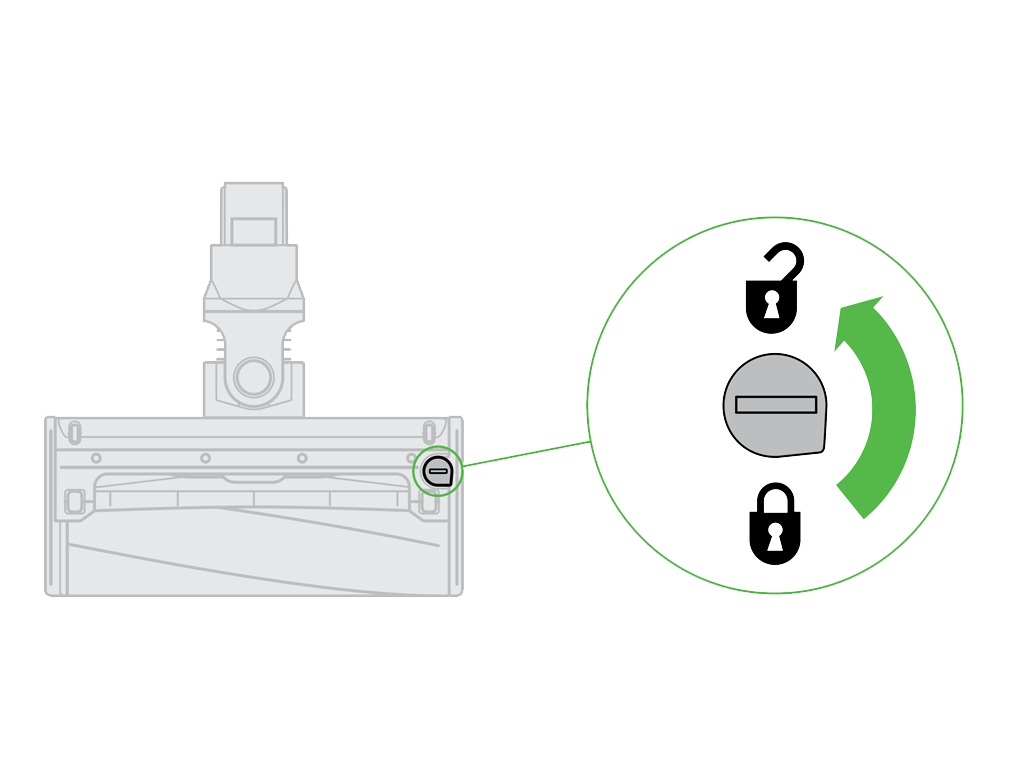

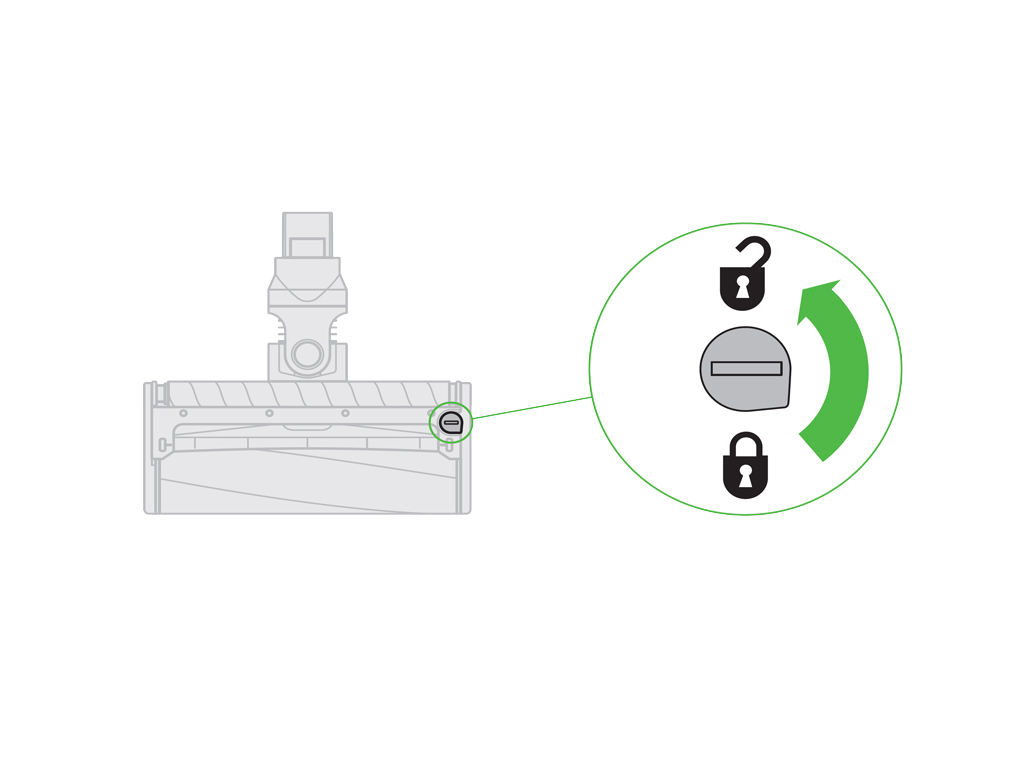

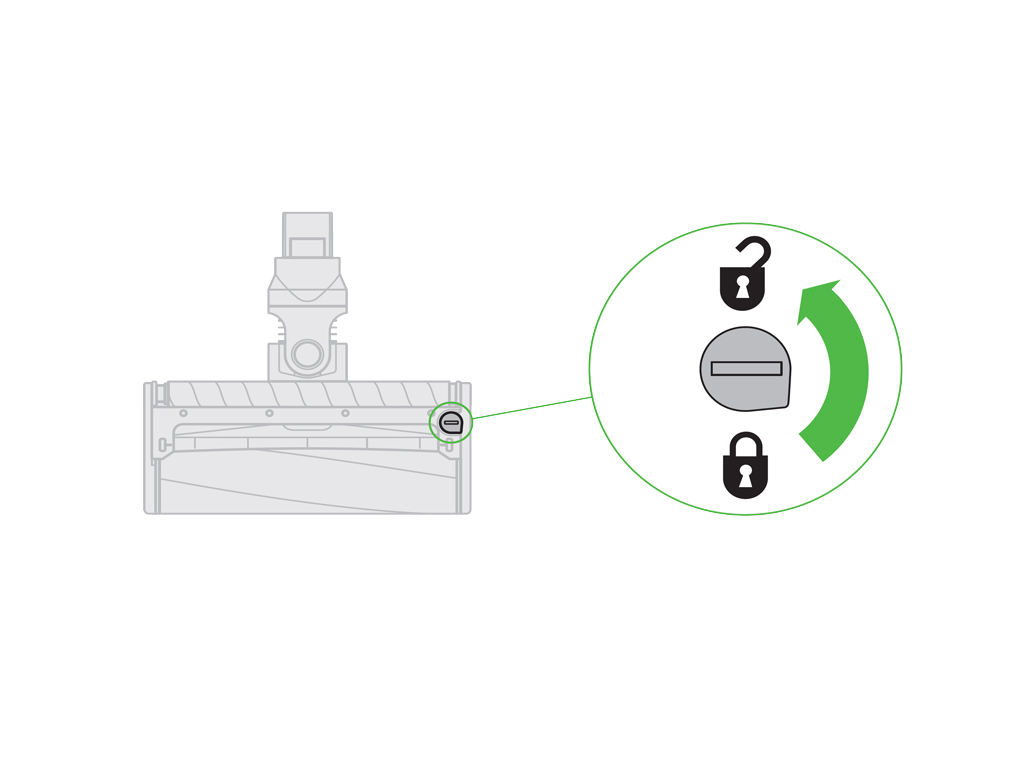

Under the cleaner head by the soft roller, locate the fastener. Using a coin, turn the fastener anticlockwise a quarter of the way to unlock the end cap, and slide it up to remove.

Remove the brush bar from the Soft roller cleaner head and clear away any hair or fibres. Check the neck of the cleaner head (where the cleaner head connects to the wand) for any blockages. Ensure there is no build-up of dust or debris in the small crevice between where the brush bar sits and the neck of the cleaner head.

The brush bar, now clear of any debris, can be reinserted into the cleaner head. Securely fasten the end cap.

The Soft roller cleaner head has two washable brush bars. Check and wash them regularly as per the step by step instructions.

Has this resolved the problem?

Please follow the steps in the video.

Washable brush bars - step by step

With the cleaner head removed from the machine, turn it upside down so the underside of the cleaner head is facing you. Use a coin to turn the end cap a quarter anticlockwise until it clicks into the unlocked position. Rotate the end cap to the open position. Gently slide the main brush bar out of the cleaner head. Remove the end cap from the main brush bar. Do not wash the end cap.

Gently slide the rear brush bar out of the cleaner head.

Hold the brush bars under running water and gently rub to remove any lint or dirt.

Stand the brush bars upright. Leave to dry completely for a minimum of 24 hours. Before replacing, check that the brush bars are completely dry.

Slide the rear brush bar back into the cleaner head.

Slide the main brush bar back into the cleaner head.

Reattach the end cap to the large brush bar.

The end cap should be in the open position. Once in place, rotate the end cap back into the closed position.

Close the fastener by turning it a quarter clockwise. Ensure that the fastener is fully turned and the brush bars are secure.

Refit the cleaner head on the machine.

Press and hold the trigger for 10 seconds.

Check the bin inlet

Check the inlet at the front of the machine for any blockages and remove as necessary.

Check the shroud opening

Hold the machine with the bin in a downwards position. Firmly push the red bin release button. The bin will slide down opening the bin base. The bin base will not open if the red button is not pushed down fully.

Check the opening on the cyclone shroud for any blockages. Remove as necessary.

Close the clear bin by pushing the bin base upwards until it clicks into place.

Press and hold the trigger for 10 seconds.

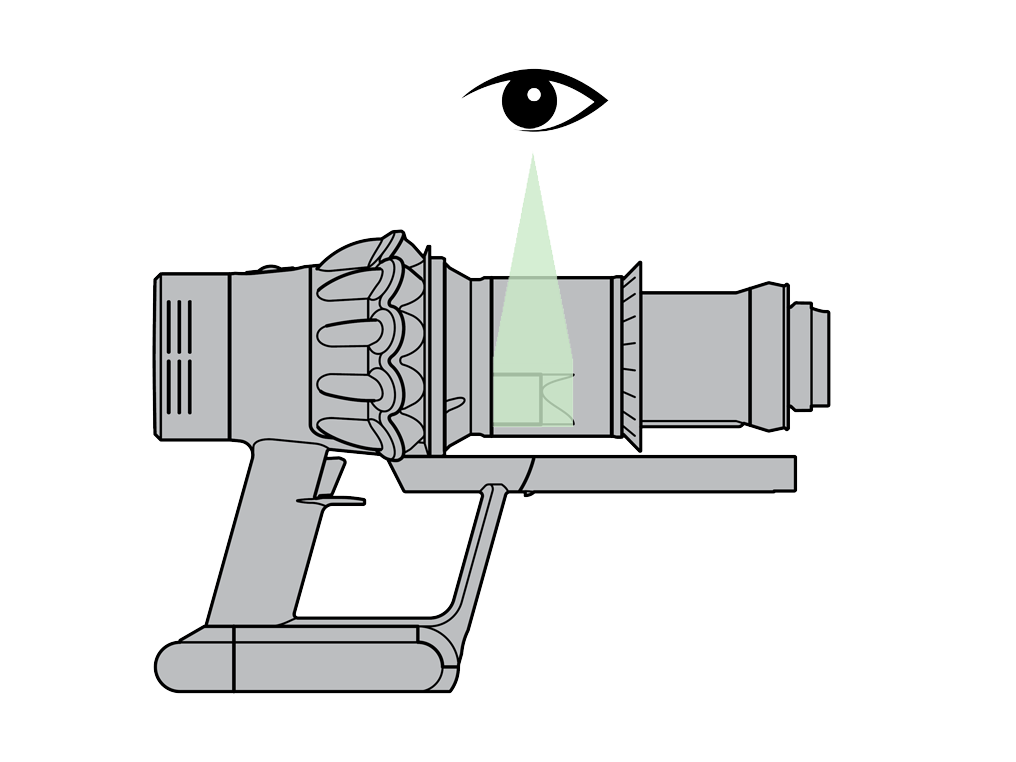

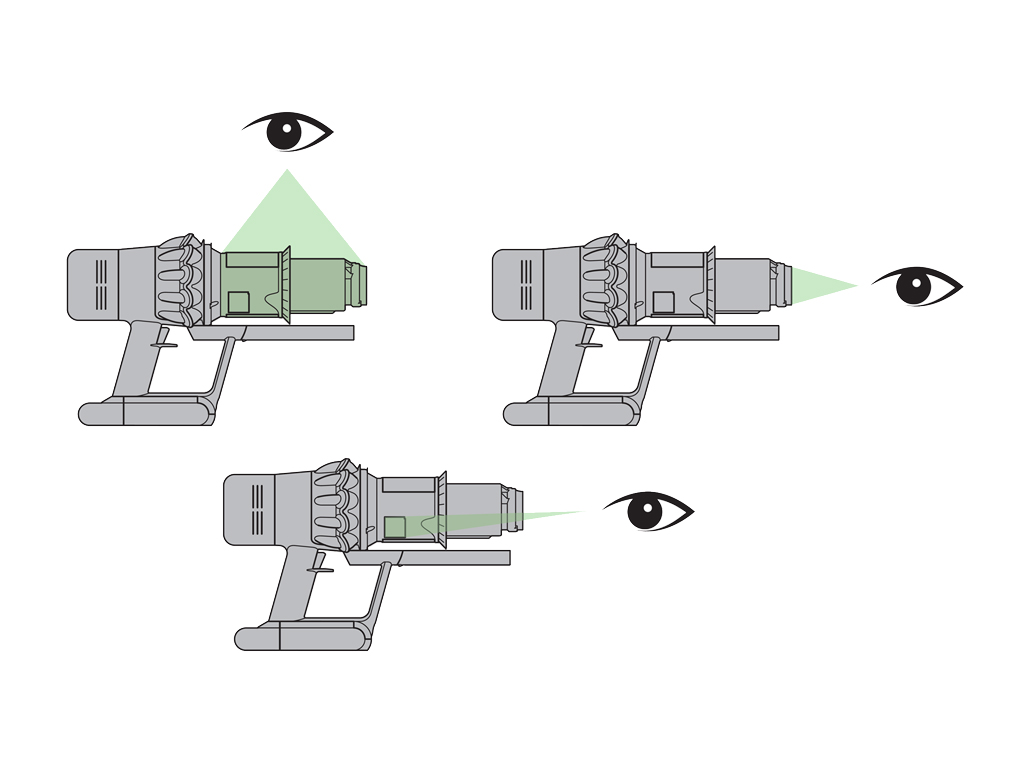

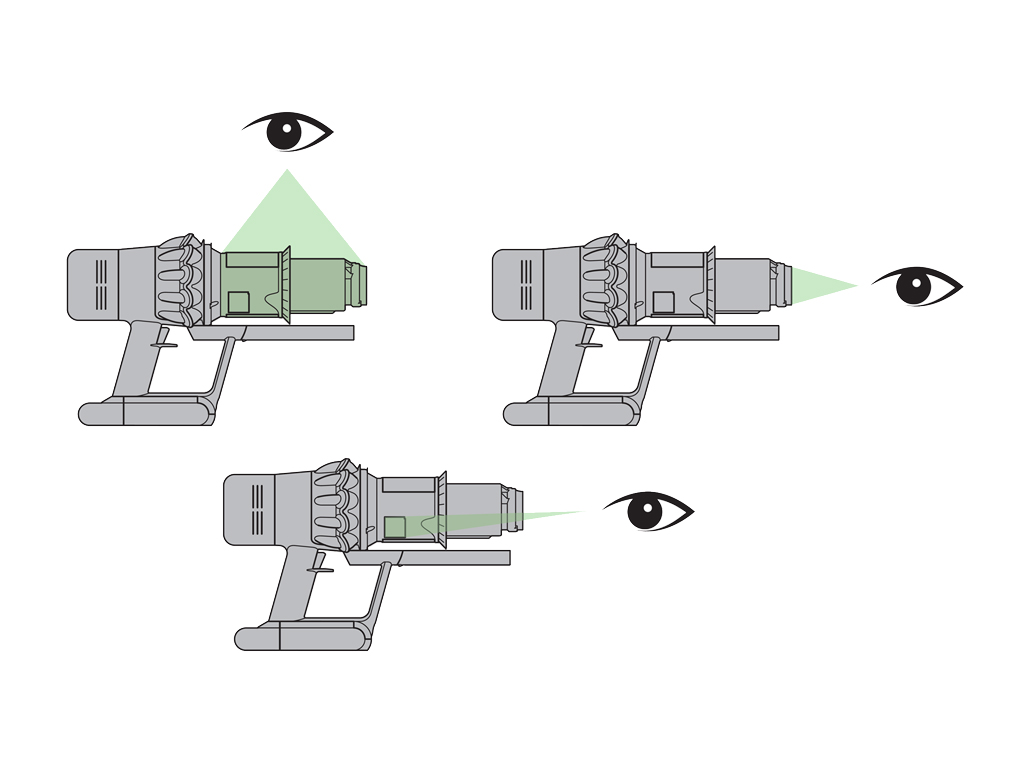

Diagnostic screen

The menu is accessed by pressing the selector button with the filter removed. Two options are displayed when accessing this menu screen.

Basic, by default is 'off'. 'On' removes the run time figures on the display screen.

Diagnostic, displays a series of numbers, letter and percentages.

Check the filter

Before exiting the menu, please ensure the filter is fitted correctly.

The filter unit should be securely fitted onto the main body and turned clockwise until it clicks into place.

Exiting the menu

Once the filter is securely in place, press and hold the selector button for approximately 10 seconds or until the screen reverts back to the main display screen.

If you are unable to revert back to the main display screen manually, it can be achieved by leaving the machine to go inactive (around 15 minutes of no interaction).

If the filter isn't correctly fitted, the machine will not turn on when pressing the trigger.

Removing the filter

Remove the filter by turning it anticlockwise. Gently pull it away from the machine.

Refit

Insert the filter back into the machine. Turn the filter clockwise until it clicks into place.

Press and hold the trigger for 10 seconds.

This alert will continue until maintenance has been carried out.

This indicates the filter needs washing. Please follow the steps in the video.

Find the text version of the step-by-step guide instead, under "Has washing the filter resolved the problem?"

Leave the filter to dry for a minimum of 24 hours in an environment with good airflow. Ensure that the filter is completely dry before reinserting it into the machine.

Press and hold the trigger for 10 seconds.

Has washing the filter resolved the problem?

Removing the filter

Remove the filter by turning it anticlockwise. Gently pull it away from the machine.

The filter may need to be washed more frequently if you are vacuuming a lot of fine dust, or if the machine is predominantly being used in Boost mode.

Gently tap the filter unit to remove any excess dust and debris before washing it.

Wash the filter in cold water only.

WARNING: Please do not use detergent, do not wash in a dishwasher or washing machine.

Wash the pleated paper element of the filter unit first; hold the filter unit under a cold water tap with the foam element downwards and run cold water over the pleated paper. Continue washing until the water runs clear.

Wash the foam element of the filter unit next; hold the filter unit under a cold water tap with the foam element downwards so that dirty water does not contaminate the pleated paper element. Run cold water over the inside and outside of the foam element and squeeze the foam gently to expel the dirt. Continue washing until the water runs clear.

Wash the outside of the filter unit. Then fill the unit with cold water, place your hands over the open ends and shake gently. Repeat washing the elements and outside of the filter unit until the water runs clear.

Gently shake the filter unit to remove any excess water and leave to drain with the foam element end facing up.

Drying

Leave the filter to dry for a minimum of 24 hours in an environment with good airflow. Ensure that the filter is completely dry before reinserting it into the machine.

Refit

Insert the filter back into the machine. Turn the filter clockwise until it clicks into place.

This alert will continue until maintenance has been carried out.

This indicates the filter needs washing. Please follow the steps in the video.

Find the text version of the step-by-step guide instead, under "Has this resolved the problem?"

Leave the filter to dry for a minimum of 24 hours in an environment with good airflow. Ensure that the filter is completely dry before reinserting it into the machine.

Press and hold the trigger for 10 seconds.

Has this resolved the problem?

Please select the appropriate option

Test the machine

Remove all tools and accessories from the machine e.g. wand, cleaner head, crevice tool etc. Please ensure the bin is empty before continuing with any checks.

Put the machine in Boost mode.

Press and hold the trigger for 10 seconds.

Does the noise still occur?

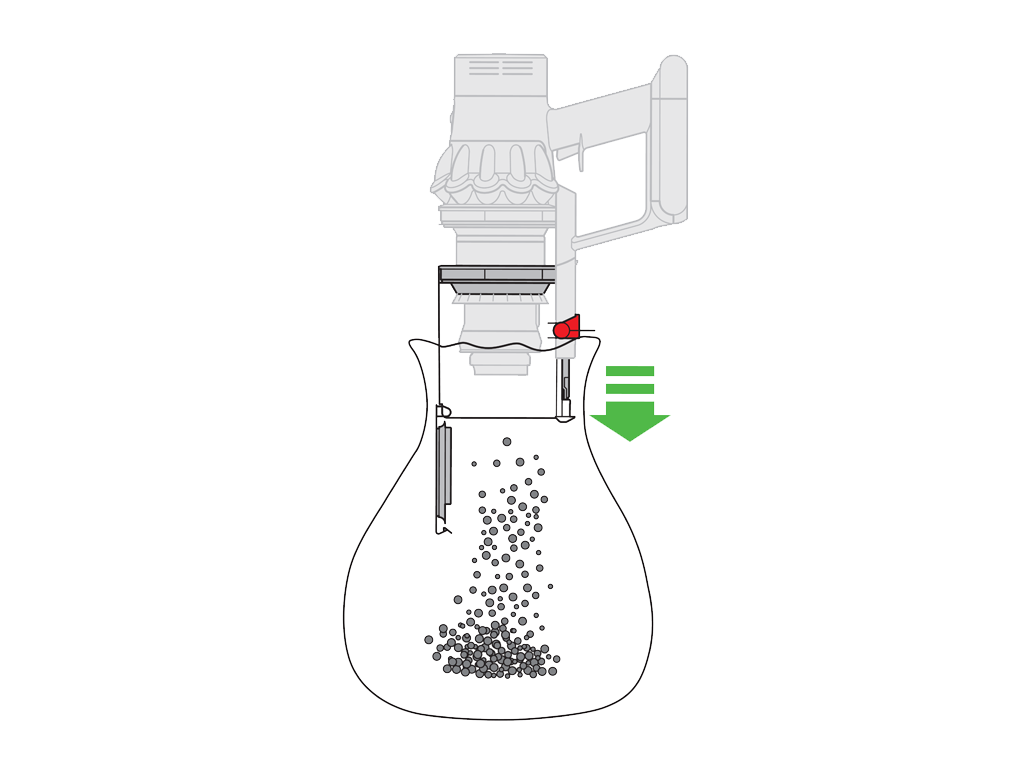

Remove the bin

Hold the machine with the bin in a downwards position. Firmly push the red bin release button. The bin will slide down opening the bin base. The bin base will not open if the red button is not pushed down fully.

Press the red button located on the bin runner to release the bin and slide the bin off the runner.

Gently tap the side of the cyclone over a bin. This will remove any fine dust clogged up in the cyclone. Using the combination tool, clean the shroud to remove any debris around the cyclone.

Press and hold the trigger for 10 seconds.

Check the bin inlet

Check the opening on the cyclone shroud for any blockages. Remove as necessary.

To refit the clear bin

Insert the spine into the bin runner.

Close the clear bin by pushing the bin base upwards until it clicks into place.

Press and hold the trigger for 10 seconds.

Please select the appropriate option

Before testing the machine please ensure that any hair or loose clothing is clear of the machine.

The suction power of the machine varies depending which power mode you have selected. Boost mode being the most powerful.

Pick up issues are typically caused by a blockage.

Be careful not to pull the 'ON' trigger while looking for blockages. Operating the machine while it is partially dismantled could result in personal injury.

Remove the tools

Remove all tools and accessories from the machine e.g. wand, cleaner head, crevice tool etc. Please ensure the bin is empty before continuing with any checks.

Press and hold the trigger for 10 seconds.

Please select the appropriate option

Automatic cut out

This machine is fitted with an automatic cut out. If any part becomes blocked, the machine may automatically cut out.

The display of your machine will alert you when simple maintenance steps are needed.

Which alert is showing?

Please ensure the battery is charged to 100% after every use.

Power modes

The machine has three power modes for different tasks. The overall run time is displayed on the digital display screen in minutes and seconds and will vary between each of the three power modes.

Run time

The overall run time can increase and decrease depending on the power mode, floor type and tool being used. Any change to the run time can take up to 30 seconds to appear on the digital display.

Is the machine working as expected?

Please ensure the battery is charged to 100% after every use.

When the machine is placed on charge it enters an idle state, this reduces all power consumption ready for the next use. Due to this reduction in the power, when the machine is removed from charge and powered on for the first time it can display an incorrect run time. This is nothing to be concerned about. The machine will assess the charge capacity and current usage within 30 seconds, displaying the correct time on the digital display.

To achieve the maximum run time, the machine must first be calibrated. The machine should be fully charged approximately five times. Between charges, use the machine until it has no battery remaining.

Where you have additional click-in batteries, we recommend alternating and charging all click-in batteries regularly to prolong battery health.

Charge the machine

Connect to the charger either directly or in the docking station.

Most Dyson vacuums have a built in safety mechanism that will turn off the machine if it begins to overheat. This typically happens when the machine is blocked, or if the filter needs washing.

If your machine continues to overheat, please allow it to cool before carrying out the performance checks.

Please select the next step

Before testing the machine please ensure that any hair or loose clothing is clear of the machine.

Automatic cut out

This machine is fitted with an automatic cut out. If any part becomes blocked, the machine may automatically cut out.

Motor is pulsating

This will happen after the motor pulses a number of times (i.e. switches on and off in quick succession) and the blockage indicator will light. Leave to cool down before looking for blockages.

Be careful not to pull the 'ON' trigger while looking for blockages. Operating the machine while it is partially dismantled could result in personal injury.

Remove the tools

Remove all tools and accessories from the machine e.g. wand, cleaner head, crevice tool etc. Please ensure the bin is empty before continuing with any checks.

Press and hold the trigger for 10 seconds.

Check for blockages

Check both ends of the wand for blockages and remove as necessary.

Reattach the cleaner head, tool or accessory to the wand. Reattach the wand to the machine.

Press and hold the trigger for 10 seconds.

Charge the machine

Connect to the charger either directly or in the docking station.

The blue LEDs – one on each side of the battery – will flash on and off during charging.

Charge the machine

When the battery is charged, both LEDs will light for 5 seconds, then go out.

Remove the charger

Press and hold the trigger for 10 seconds.

Pull the trigger

Press and hold the trigger for 10 seconds.

The LED lights should be on constantly when in use.

If the LED lights blink on/off for approximately 10 seconds when the trigger is pulled, please select 'LED lights blinking'.

Do the blue LED lights appear on either side of the battery?

Charging

If the machine is being charged through the docking station, please disconnect the charger and connect it directly into the machine.

Please check household electrics or use an alternative plug socket.

Remove the charger

Press and hold the trigger for 10 seconds.

The blue LEDs – one on each side of the battery – will flash on and off during charging.

When the battery is charged, both LEDs will light for 5 seconds, then go out.

The machine can take up to 4.5 hours to fully charge.

Remove the charger

Press and hold the trigger for 10 seconds.

The Dyson V11™ battery and monitoring system work together to gauge how much run time is remaining. The system calculates run time using an algorithm that ‘learns’ how your machine works over time. To get the best experience, we recommend fully charging your machine after every use. This helps the battery and monitoring system's algorithm to more accurately calculate and display remaining run time.

The actual run time of your machine remains unaffected while the algorithm learns to more accurately gauge remaining power.

The battery is designed to be left on charge permanently, and this will ensure that the machine is fully charged when it's next used. It will take up to 4.5 hours to fully charge your machine. Once the battery is fully charged, your machine won't use any more electricity.

If your machine continues to cut out even though run time remains on the screen, we recommend fully charging your machine, then using it continuously until the battery runs out. This should be completed within one cleaning session, but the trigger doesn't need to be held down throughout. We advise using Auto/Med mode for this clean. The more this process is repeated, the more accurate the algorithm becomes.

The battery is designed to be left on charge permanently, and this will ensure that the machine is fully charged when it's next used. It will take up to 4.5 hours to fully charge your machine. Once the battery is fully charged, your machine won't use any more electricity.

Please select the appropriate option

Damp or musty

A damp or musty smell is caused when dust in the cyclone has come into contact with water.

It may not be a direct contact with water, for example when vacuuming pet hair that is slightly damp, this moisture will combine with the dust in the cyclone causing the smell.

Additionally the smell may occur if the filter goes back into the machine wet.

Only the filter and the two washable brush bars from the Soft roller cleaner head can be washed. The bin can be cleaned with a damp cloth only. Washed and cleaned parts must be completely dry before being refitted to the machine.

Remove the bin

Hold the machine with the bin in a downwards position. Firmly push the red bin release button. The bin will slide down opening the bin base. The bin base will not open if the red button is not pushed down fully.

Press the red button located on the bin runner to release the bin and slide the bin off the runner.

Gently tap the side of the cyclone over a bin. This will remove any fine dust clogged up in the cyclone. Using the combination tool, clean the shroud to remove any debris around the cyclone.

Check the opening on the cyclone shroud for any blockages. Remove as necessary.

The clear bin is not dishwasher safe and the use of detergents, polishes or air fresheners to clean the clear bin is not recommended as this may damage your machine. Clean the clear bin with a damp cloth only.

To refit the clear bin

Insert the spine into the bin runner.

Close the clear bin by pushing the bin base upwards until it clicks into place.

This indicates the filter needs washing. Please follow the steps in the video.

Find the text version of the step-by-step guide instead, under "Has this resolved the problem?"

Leave the filter to dry for a minimum of 24 hours in an environment with good airflow. Ensure that the filter is completely dry before reinserting it into the machine.

Press and hold the trigger for 10 seconds.

Has this resolved the problem?

Damp or musty smell still present

Under normal use, any unpleasant smell can only be caused by something the machine has picked up. Please select pick up issues to carry out checks.

Please select the next step

Removing the filter

Remove the filter by turning it anticlockwise. Gently pull it away from the machine.

Gently tap the filter unit to remove any excess dust and debris before washing it.

Wash the filter in cold water only.

WARNING: Please do not use detergent, do not wash in a dishwasher or washing machine.

Wash the pleated paper element of the filter unit first; hold the filter unit under a cold water tap with the foam element downwards and run cold water over the pleated paper. Continue washing until the water runs clear.

Wash the foam element of the filter unit next; hold the filter unit under a cold water tap with the foam element downwards so that dirty water does not contaminate the pleated paper element. Run cold water over the inside and outside of the foam element and squeeze the foam gently to expel the dirt. Continue washing until the water runs clear.

Wash the outside of the filter unit. Then fill the unit with cold water, place your hands over the open ends and shake gently. Repeat washing the elements and outside of the filter unit until the water runs clear.

Gently shake the filter unit to remove any excess water and leave to drain with the foam element end facing up.

Drying

Leave the filter to dry for a minimum of 24 hours in an environment with good airflow. Ensure that the filter is completely dry before reinserting it into the machine.

Refit

Insert the filter back into the machine. Turn the filter clockwise until it clicks into place.

The filter may need to be washed more frequently if you are vacuuming a lot of fine dust, or if the machine is predominantly being used in Boost mode.

Damp or musty smell still present

Under normal use, any unpleasant smell can only be caused by something the machine has picked up. Please select pick up issues to carry out checks.

If you are able to identify which part of the machine the smell is coming from, replacing this part may resolve the issue.

Please select the appropriate option

Please select the appropriate option

Please check all floor tools

Please connect the floor tool directly on to the bin.

If the brush bar on every tool spins when connected to the bin, please select "The wand is damaged".

If the brush bar isn't spinning on any tool, please select "The brush bar does not spin on any cleaner head".

Turn the cleaner head upside down so the underside of the cleaner head is facing you.

Push the end cap upwards until it opens and pull the brush bar out of the cleaner head.

Remove any debris from the brush bar.

Slide the Brush bar back onto the Cleaner head, around the motor. The end cap should be in the open position as shown.

Push the end cap until it clips securely back into the closed position.

Has this resolved the problem?

Clear the floor tool

With the Direct drive cleaner head removed from the machine, turn it over and undo the fastener.

Locate the end cap and using a coin, turn it anticlockwise a quarter of the way. This will allow you to remove it.

Note: There should be a small padlock icon along with directional arrows to help you unlock the end cap.

Remove the brush bar from the Direct drive cleaner head and clear away any hair or fibres. Check the neck of the cleaner head (where the cleaner head connects to the wand) for any blockages. Ensure there is no build-up of dust or debris in the small crevice between where the brush bar sits and the neck of the cleaner head.

The brush bar, now clear of any debris, can be reinserted into the cleaner head. Securely fasten the end cap.

For deep pile rugs or carpets you may find the brush bar stops spinning when moved close to the positive position. This is to protect both the machine and the carpet itself.

Clear the floor tool

With the High Torque cleaner head removed from the machine, turn it over and undo the fastener.

Locate the end cap and using a coin, turn it anticlockwise a quarter of the way. This will allow you to remove it.

Note: There should be a small padlock icon along with directional arrows to help you unlock the end cap.

Remove the brush bar from the High Torque cleaner head and clear away any hair or fibres. Check the neck of the cleaner head (where the cleaner head connects to the wand) for any blockages. Ensure there is no build-up of dust or debris in the small crevice between where the brush bar sits and the neck of the cleaner head.

The brush bar, now clear of any debris, can be reinserted into the cleaner head. Securely fasten the end cap.

Place the cleaner head onto the bin, change the suction control slider to the positive position and test the machine.

Switch the suction control slider to the negative setting and continue testing.

Clear the floor tool

With the Quick-release Mini motorised head removed from the machine, turn it over and undo the fastener. Locate the end cap and using a coin, turn it anticlockwise a quarter of the way. This will allow you to remove it.

Note: There should be a small padlock icon along with directional arrows to help you unlock the end cap.

Remove the brush bar from the Quick-release Mini motorised head and clear away any hair or fibres. Check the neck of the cleaner head (where the cleaner head connects to the wand) for any blockages. Ensure there is no build-up of dust or debris in the small crevice between where the brush bar sits and the neck of the cleaner head.

The brush bar, now clear of any debris, can be reinserted into the cleaner head. Securely fasten the end cap.

Clear the floor tool

With the cleaner head removed from the machine, turn it over. On the underside of the cleaner head by the soft roller, locate the fastener. Using a coin, turn the fastener anticlockwise a quarter of the way to remove the end cap.

Note: There should be a small padlock icon along with directional arrows to help you unlock the end cap.

Remove the brush bar from the Soft roller cleaner head and clear away any hair or fibres. Check the neck of the cleaner head (where the cleaner head connects to the wand) for any blockages. Ensure there is no build-up of dust or debris in the small crevice between where the brush bar sits and the neck of the cleaner head.

The brush bar, now clear of any debris, can be reinserted into the cleaner head. Securely fasten the end cap.

The Soft roller cleaner head has two washable brush bars. Check and wash them regularly as per the step by step instructions.

Has this resolved the problem?

Please follow the steps in the video.

Washable brush bars - step by step

With the cleaner head removed from the machine, turn it upside down so the underside of the cleaner head is facing you. Use a coin to turn the end cap a quarter anticlockwise until it clicks into the unlocked position. Rotate the end cap to the open position. Gently slide the main brush bar out of the cleaner head. Remove the end cap from the main brush bar. Do not wash the end cap.

Gently slide the rear brush bar out of the cleaner head.

Hold the brush bars under running water and gently rub to remove any lint or dirt.

Stand the brush bars upright. Leave to dry completely for a minimum of 24 hours. Before replacing, check that the brush bars are completely dry.

Slide the rear brush bar back into the cleaner head.

Slide the main brush bar back into the cleaner head.

Reattach the end cap to the large brush bar.

The end cap should be in the open position. Once in place, rotate the end cap back into the closed position.

Close the fastener by turning it a quarter clockwise. Ensure that the fastener is fully turned and the brush bars are secure.

Refit the cleaner head on the machine.

Press and hold the trigger for 10 seconds.

Has this resolved the problem?

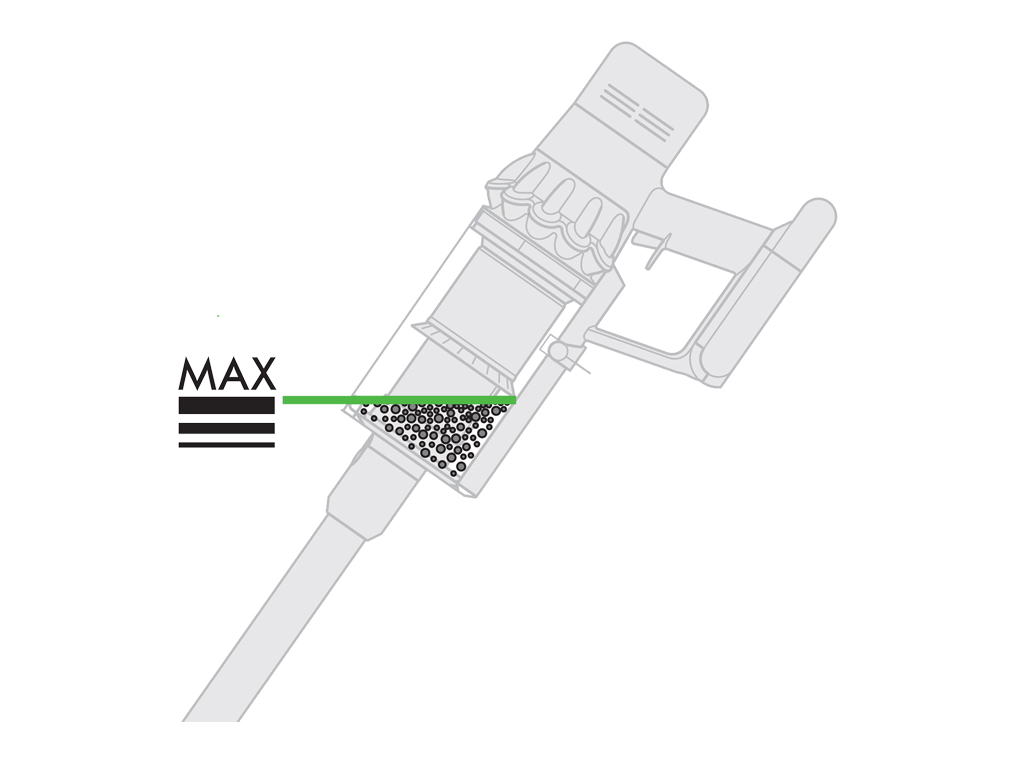

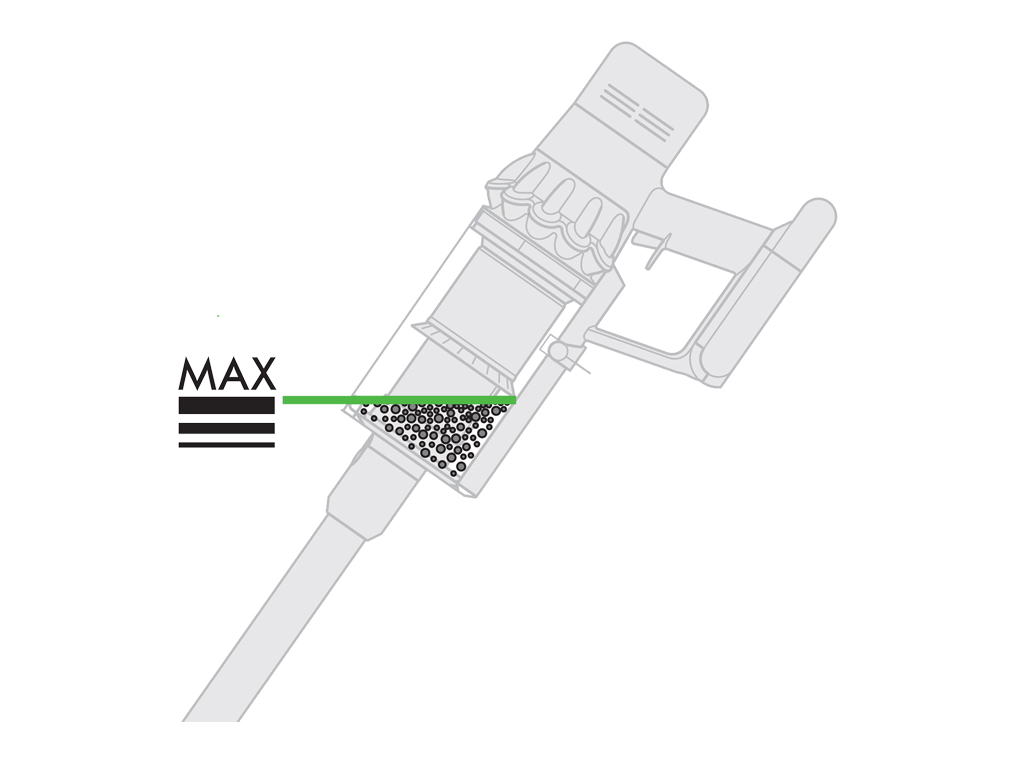

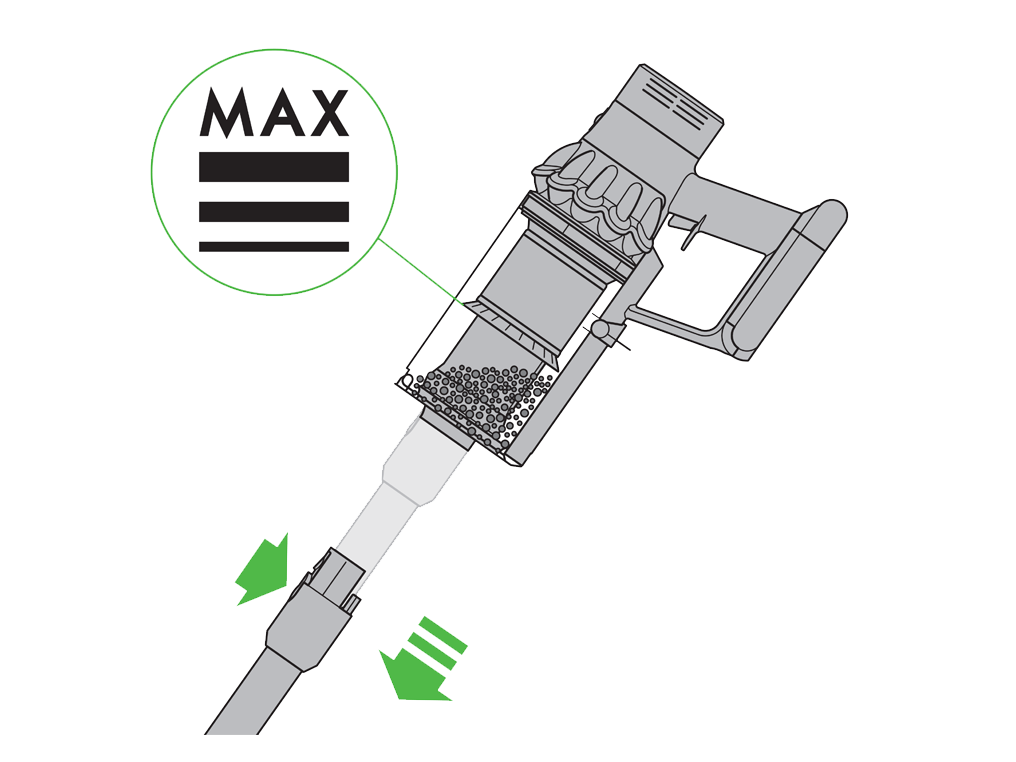

Please ensure that you are emptying the bin as soon as the dirt reaches the level of the MAX mark.

Should the dirt in the bin exceed the MAX mark, the excess dirt can be pulled directly into the filter causing a blockage.

Has this resolved the problem?

Please follow the steps in the video.

Has this resolved the problem?

Empty as soon as the dirt reaches the level of the MAX mark - do not overfill. Ensure the machine is disconnected from the charger before emptying the clear bin. Be careful not to pull the 'ON' trigger.

Remove the wand by pressing the red wand release button and pulling away from the bin.

Emptying the bin

Hold the machine with the bin in a downwards position. Firmly push the red bin release button. The bin will slide down opening the bin base. The bin base will not open if the red button is not pushed down fully.

Closing the bin

Close the clear bin by pushing the bin base upwards until it clicks into place.

Scratches or marks on the wand

Marks on the wand can be caused by making contact with a painted surface such as a door frame.

These can be removed by wiping them with a damp cloth.

Further help

Dyson Outsize Absolute