Let's get your machine working

DC08 Allergy™

Let's get your machine working

DC08 Allergy™

-

-

Checking for blockages

-

Check the floor tool

-

Issue resolved

-

Check for blockages

-

Checking the duct, cyclone and bin

-

Washing the filter

-

Issue not resolved, please speak to our Customer Support Team

-

Issue not resolved, please speak to our Customer Support Team

-

Check Wand and hose

-

Check the duct, bin and cyclone

-

Wash the filter

-

Check the floor tool

-

Issue not resolved, please speak to our Customer Support Team

-

Emptying the bin

-

More help required

-

Troubleshooting

-

Unusual noise

-

Issue not resolved, please speak to our Customer Support Team

-

Rattle noise

-

Issue not resolved, please speak to our Customer Support Team

-

Clean the bin and cyclone

-

Check extension tube, wand handle and hose

-

Check the floor tool

-

Whistle noise

-

Check the hose

-

Check the floor tool

-

Check Turbine head

-

Check Turbine head

-

Performance checks

-

Check duct, bin and cyclone

-

Check the floor tool

-

Check the floor tool

-

Check duct, bin and cyclone

-

Check hose, Wand handle and extension tube

-

Check the floor tool

-

Check the Dual mode floor tool

-

Check the contact head

-

Check the Turbine head

-

Check the floor tool

-

Pick up issues

-

Check the floor tool

-

Power or electrical issue

-

Issue not resolved, please speak to our Customer Support Team

-

No power

-

Less than two hours

-

More than two hours

-

Switch not working

-

Issue not resolved, please speak to our Customer Support Team

-

Issue not resolved, please speak to our Customer Support Team

-

Unusual smell

-

Issue not resolved, please speak to our Customer Support Team

-

Musty or damp smell

-

Visible issue

-

Cable won't rewind

-

Issue not resolved, please speak to our Customer Support Team

-

Spitting out dust

-

Washing the filter

-

Washing the filter - step by step

-

New question

-

User guide

-

More help required

-

Check for blockages

-

Check for blockages

-

Check the duct, bin and cyclone

-

Check the filter

-

Check the floor tool

-

Issue not resolved, please speak to our Customer Support Team

-

Check the floor tool

-

Check for blockages

-

Checking the duct, cyclone and bin

-

Emptying the bin

-

Issue resolved

-

Cleaning the bin and cyclone

-

Washing the filter

-

Washing the filter - step by step

-

How to find the serial number

-

How to attach the accessories

-

How to use the Mini turbine head

-

How to use the telescopic wand

-

Check the floor tool

-

Check Mini turbine head

-

Performance checks

-

Test the suction

-

Check for blockages

-

Issue not resolved, please speak to our Customer Support Team

-

User guide

-

Issue resolved

-

How to find the serial number

-

How to attach the accessories

-

How to use the Mini turbine head

-

How to use the extension tube

-

Cleaning the bin and cyclone

-

We need a little more information to help us solve your issue.

Please contact our customer service team on 01-475-7109, or directly on Live Chat through our Digital Assistant by clicking the purple icon at the bottom of the page. You can start a conversation with an Expert by clicking the agent icon at the bottom left of the chat window.

We need a little more information to help us solve your issue.

Please contact our customer service team on 01-475-7109, or directly on Live Chat through our Digital Assistant by clicking the purple icon at the bottom of the page. You can start a conversation with an Expert by clicking the agent icon at the bottom left of the chat window.

We need a little more information to help us solve your issue.

Please contact our customer service team on 01-475-7109, or directly on Live Chat through our Digital Assistant by clicking the purple icon at the bottom of the page. You can start a conversation with an Expert by clicking the agent icon at the bottom left of the chat window.

We need a little more information to help us solve your issue.

Please contact our customer service team on 01-475-7109, or directly on Live Chat through our Digital Assistant by clicking the purple icon at the bottom of the page. You can start a conversation with an Expert by clicking the agent icon at the bottom left of the chat window.

We need a little more information to help us solve your issue.

Please contact our customer service team on 01-475-7109, or directly on Live Chat through our Digital Assistant by clicking the purple icon at the bottom of the page. You can start a conversation with an Expert by clicking the agent icon at the bottom left of the chat window.

We need a little more information to help us solve your issue.

Please contact our customer service team on 01-475-7109, or directly on Live Chat through our Digital Assistant by clicking the purple icon at the bottom of the page. You can start a conversation with an Expert by clicking the agent icon at the bottom left of the chat window.

We need a little more information to help us solve your issue.

Please contact our customer service team on 01-475-7109, or directly on Live Chat through our Digital Assistant by clicking the purple icon at the bottom of the page. You can start a conversation with an Expert by clicking the agent icon at the bottom left of the chat window.

We need a little more information to help us solve your issue.

Please contact our customer service team on 01-475-7109, or directly on Live Chat through our Digital Assistant by clicking the purple icon at the bottom of the page. You can start a conversation with an Expert by clicking the agent icon at the bottom left of the chat window.

We need a little more information to help us solve your issue.

Please contact our customer service team on 01-475-7109, or directly on Live Chat through our Digital Assistant by clicking the purple icon at the bottom of the page. You can start a conversation with an Expert by clicking the agent icon at the bottom left of the chat window.

We need a little more information to help us solve your issue.

Please contact our customer service team on 01-475-7109, or directly on Live Chat through our Digital Assistant by clicking the purple icon at the bottom of the page. You can start a conversation with an Expert by clicking the agent icon at the bottom left of the chat window.

We need a little more information to help us solve your issue.

Please contact our customer service team on 01-475-7109, or directly on Live Chat through our Digital Assistant by clicking the purple icon at the bottom of the page. You can start a conversation with an Expert by clicking the agent icon at the bottom left of the chat window.

We need a little more information to help us solve your issue.

Please contact our customer service team on 01-475-7109, or directly on Live Chat through our Digital Assistant by clicking the purple icon at the bottom of the page. You can start a conversation with an Expert by clicking the agent icon at the bottom left of the chat window.

We're glad the problem's been solved.

Please let us know if there's anything else we can help you with.

The Dyson guarantee

'How to ' videos and tips

Exclusive owner benefits

Expert advice. 7 days a week.

Hassle-free repairs and replacement

We need a little more information to help us solve your issue.

Please contact our customer service team on 01-475-7109, or directly on Live Chat through our Digital Assistant by clicking the purple icon at the bottom of the page. You can start a conversation with an Expert by clicking the agent icon at the bottom left of the chat window.

We're glad the problem's been solved.

Please let us know if there's anything else we can help you with.

The Dyson guarantee

'How to ' videos and tips

Exclusive owner benefits

Expert advice. 7 days a week.

Hassle-free repairs and replacement

Please select the appropriate option

Test the suction from the extension tube

Remove the floor tool from the extension tube by pressing the release catch on the floor tool.

Grip cuff firmly to extend extension tube fully, ensuring it can extend no further.

Place your hand over the end of the extension tube and test the suction.

Is the suction strong or weaker than usual?

Check the floor tool

Remove the floor tool from the metal extension tube by pressing the push button located on the floor tool.

Check the opening of the floor tool for blockages and remove if necessary.

You can change the resistance of the floor tool by adjusting the red airflow ports on its base.

Push the tabs inwards to ensure best resistance.

Reassemble and test the machine.

If the floor tool is damaged choose the 'part broken' option.

Check for blockages

Remove the hose from the Main body.

Pull hose out of the inlet.

Press back cuff release catch and remove from the Main body.

Detach the Wand handle from the hose and extension tube.

Check for blockages and remove as necessary

Check both ends of the flexible hose, extension tube and the Wand for blockages and remove as necessary.

Reassemble and test machine.

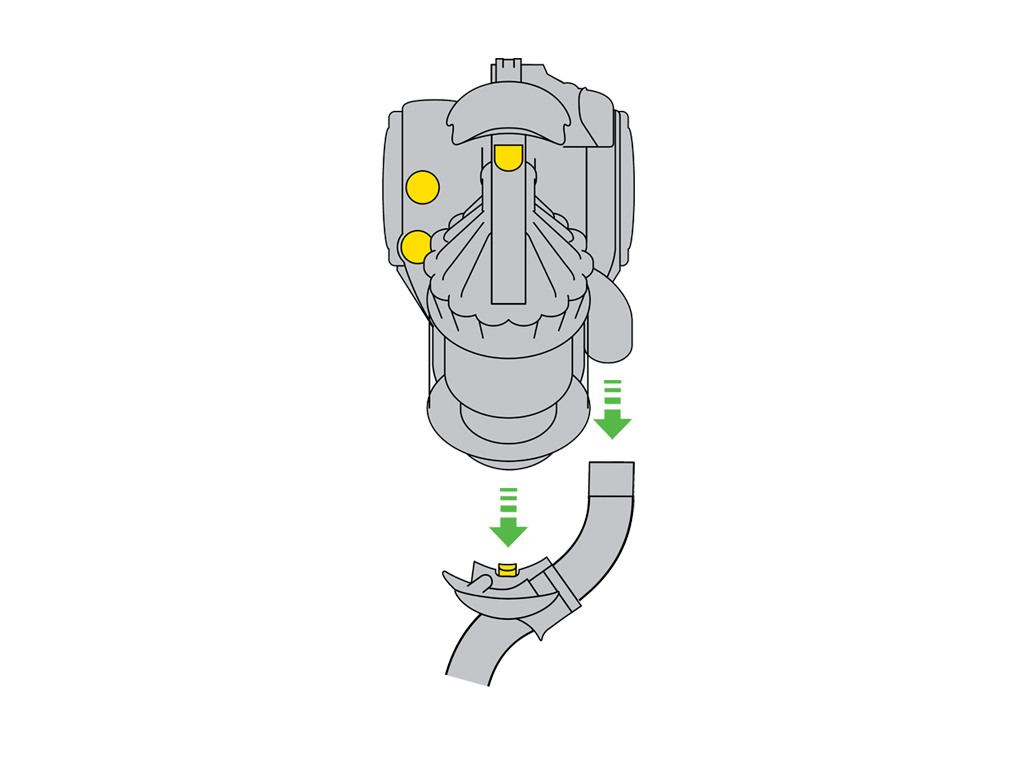

Checking the duct, cyclone and bin

Remove the bin by pressing the catch on top of the handle.

Remove the cyclone from the bin by pressing the release catch on top of the clear handle.

Clean the shroud with a cloth or dry brush to remove the fluff and dust.

Check the bin and cyclone

Ensure the bin inner is clear and large cone seal is not missing or damaged.

Ensure the cyclone is clean and remove blockages as necessary. Tap cyclone to remove tougher debris.

Checking the duct

Check the duct inlet for blockages and remove as necessary.

Open the pre-filter cover and remove blockages as necessary.

Close the pre-filter cover lid ensuring the filter is inside, reconnect the bin and cyclone and attach to the machine.

If any parts are missing or damaged choose part broken to place an order.

Retest the machine.

Washing the filter

Please follow the steps in the video to wash the filter.

For a step by step guide, please select step by step.

Has washing the filter resolved the problem?

Check for blockages

Remove the hose from the Main body.

Pull hose out of the inlet.

Press back cuff release catch and remove from the Main body.

Detach the Wand handle from the hose and extension tube.

Check for blockages and remove as necessary

Check for blockages and remove as necessary.

Check both ends of the flexible hose.

Check both ends of the Wand handle.

Check both ends of the extension tube.

Reassemble and test the machine.

Checking the duct, cyclone and bin

Remove the bin by pressing the catch on top of the handle.

Remove the cyclone from the bin by pressing the release catch on top of the clear handle.

Clean the shroud with a cloth or dry brush to remove the fluff and dust.

Check the bin and cyclone

Ensure the bin inner is clear and large cone seal is not missing or damaged.

Ensure the cyclone is clean and remove blockages as necessary. Tap cyclone to remove tougher debris.

Checking the duct

Check the duct inlet for blockages and remove as necessary.

Open the pre-filter cover and remove blockages as necessary.

Close the pre-filter cover lid ensuring the filter is inside, reconnect the bin and cyclone and attach to the machine.

If any parts are missing or damaged, please select 'Part broken'.

Retest the machine.

The post-motor filter located under the clear bin should last the lifetime of the machine and does not need to be washed.

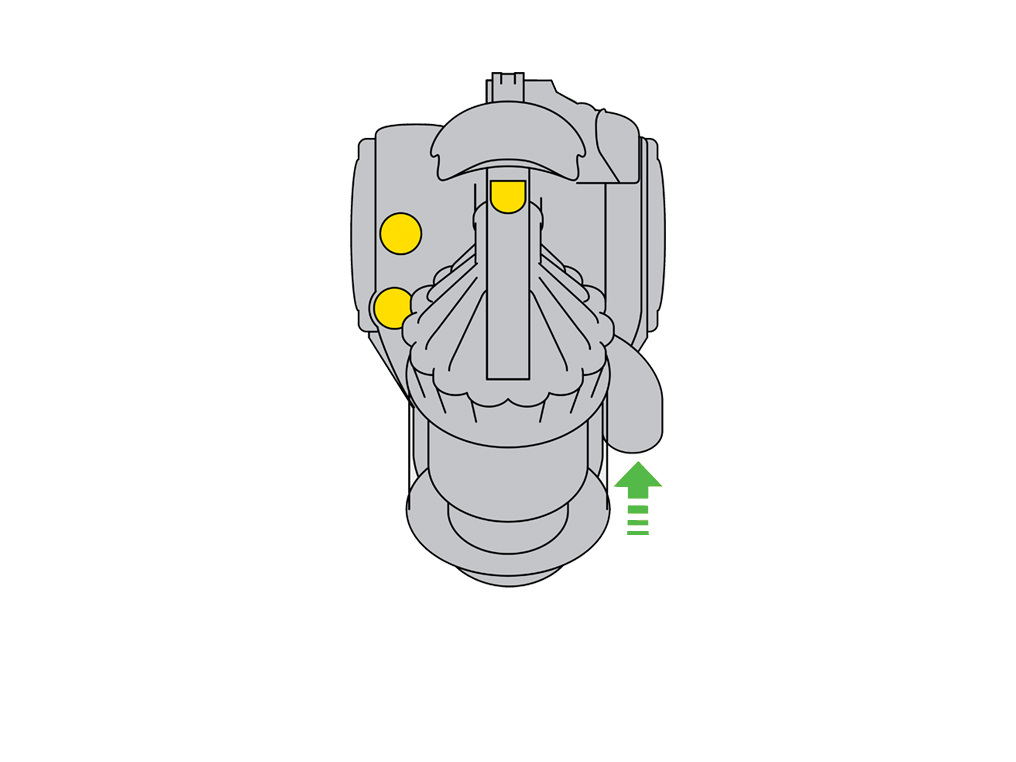

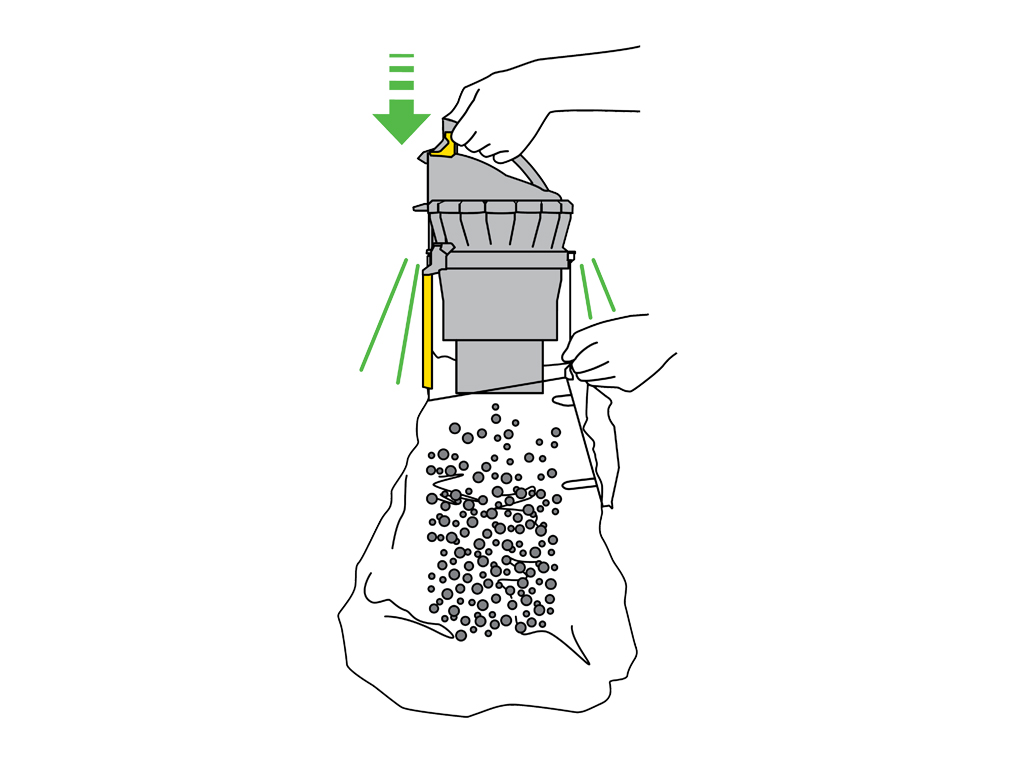

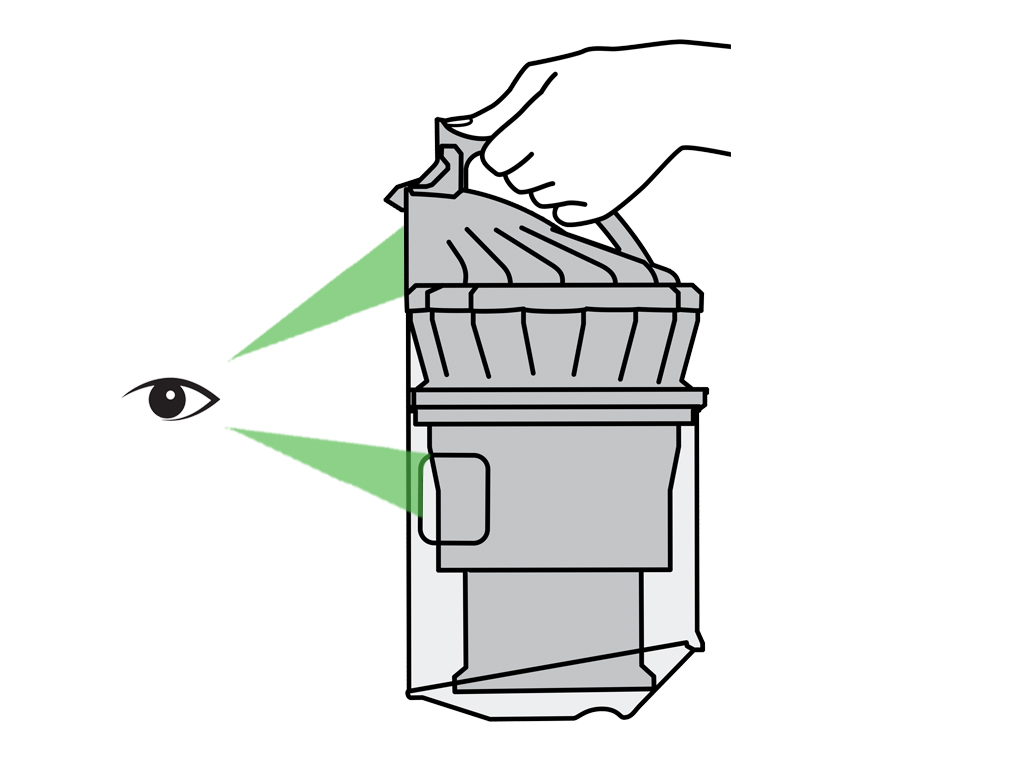

Remove the filters

Turn power off and unplug the machine.

Press the release catch on the cyclone and remove the filter and filter casing from the machine.

Wash the filter

Wash the filter in cold water only.

WARNING: Please do not use detergent, do not wash in a dishwasher or washing machine.

Wash the filter case in cold water only.

Dry the filter

Leave the filter to dry in a warm place for 12 hours, until completely dry.

Do not dry the filter in a tumble dryer, microwave, oven or near a naked flame.

The filter should be washed at least once every 6 months.

If the filter is missing or damaged choose 'part broken'.

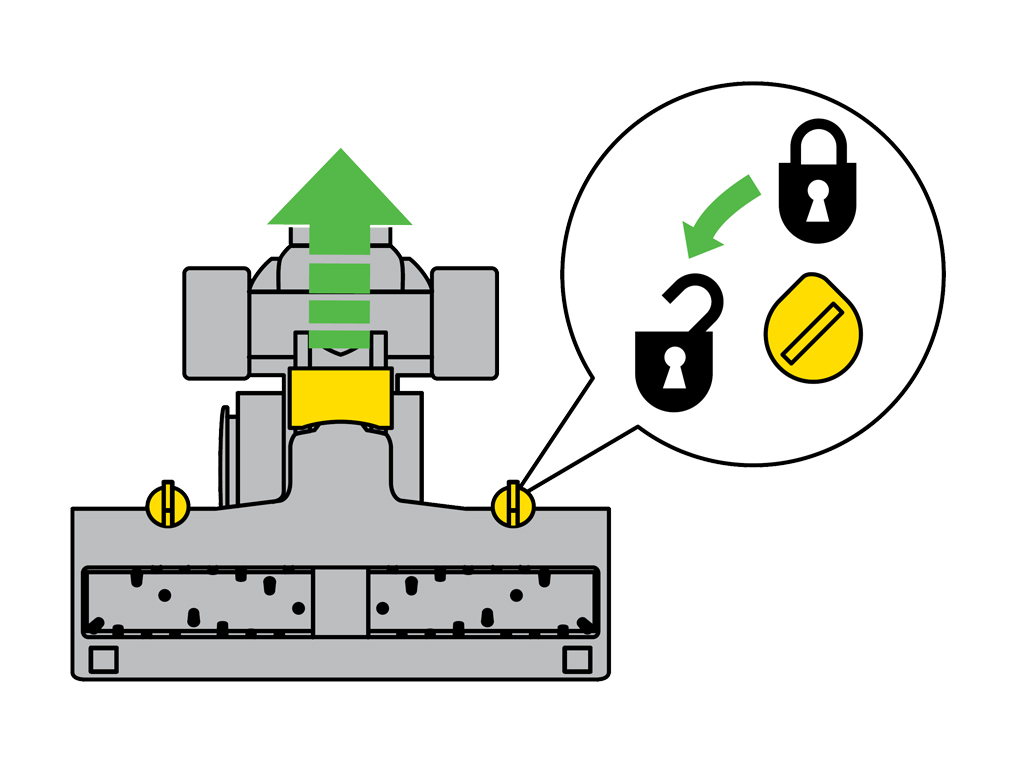

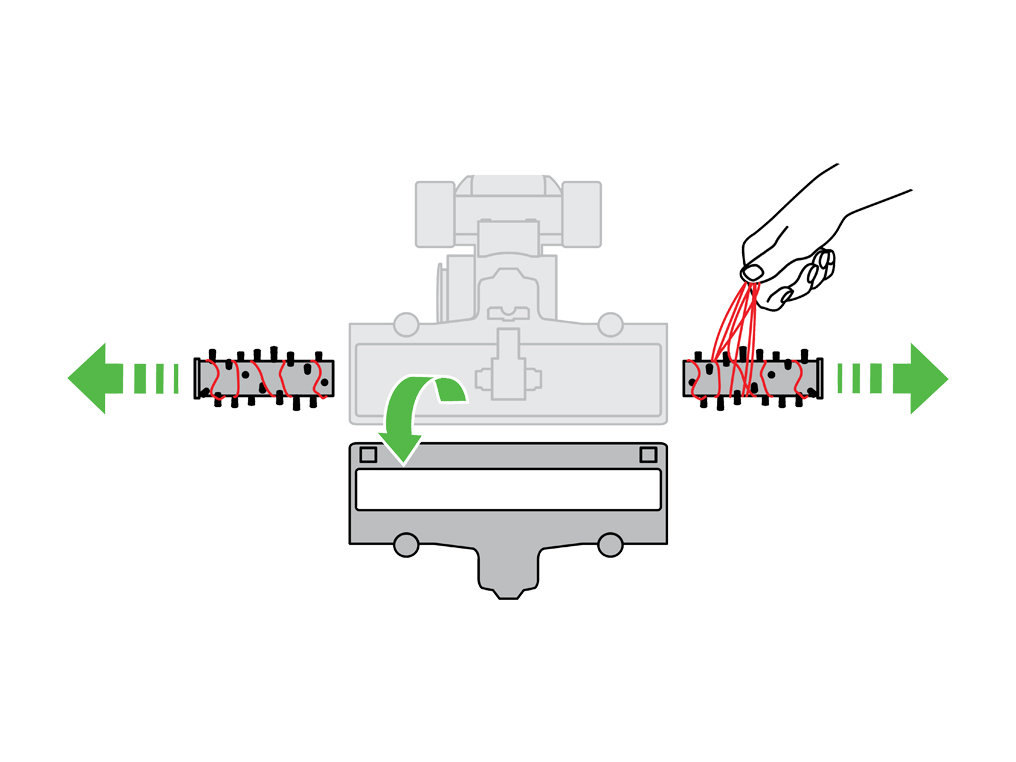

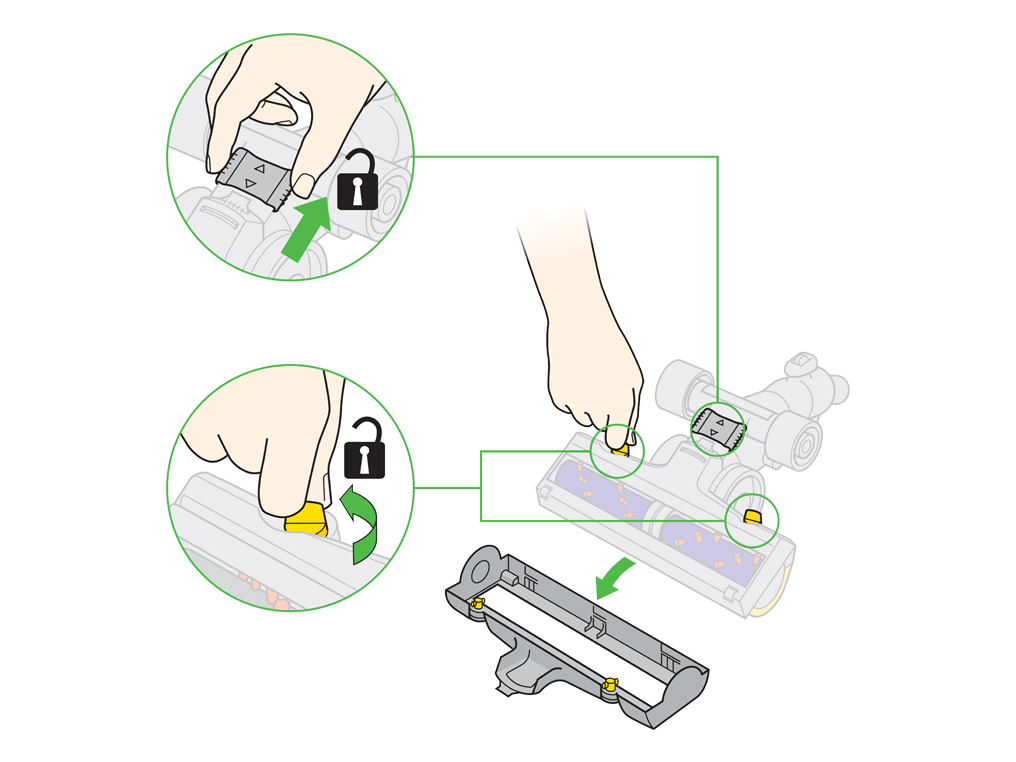

Check the floor tool

Press the release button on the Turbine head to remove from the Extension tube.

Slide back the soleplate catch and turn the two fasteners by a quarter.

Check for blockages

Remove the Brush bars and clear any hair, thread and debris

Check both of the metal shafts for blockages and ensure they rotate freely by hand

Inspect the duct on the underside of the Turbine head for blockages and remove if necessary.

Check the outside surface of the plunger for fluff and debris and remove if necessary.

Check the outside surface of the plunger for fluff and debris and remove if necessary.

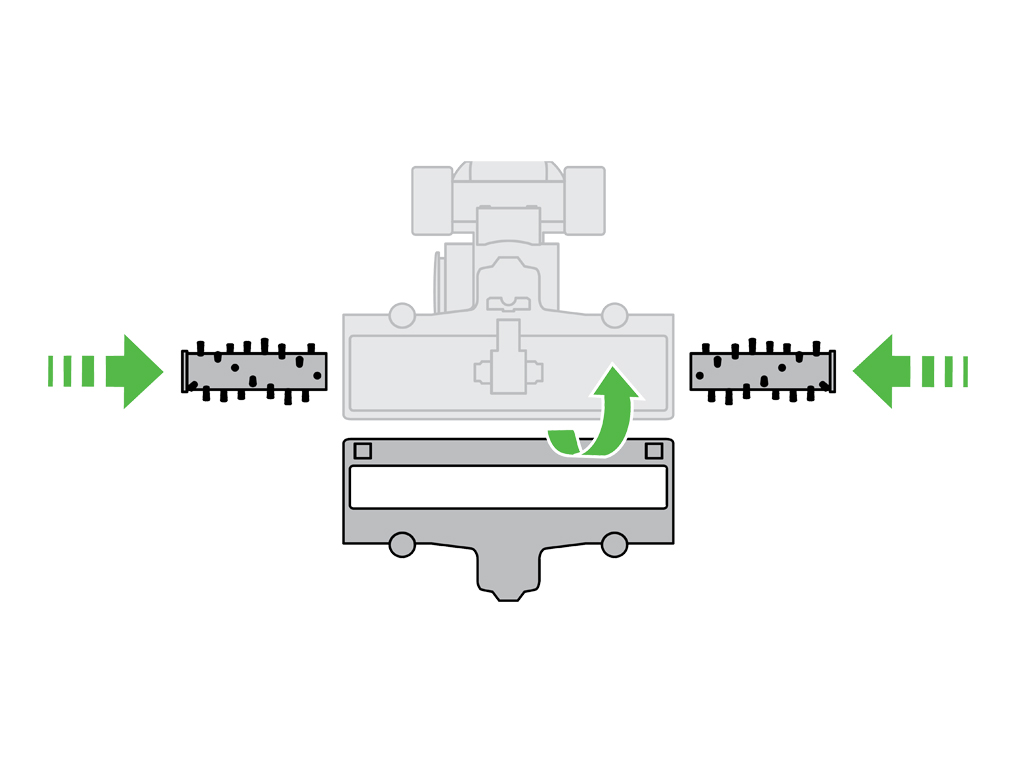

When replacing the Brush bars please ensure that both the arrows on the Brush bars are pointing in the same direction towards the wheels on the Turbine head.

Replace soleplate locking the front tabs first and reclining the soleplate down, lock the two fasteners and slide back the soleplate catch.

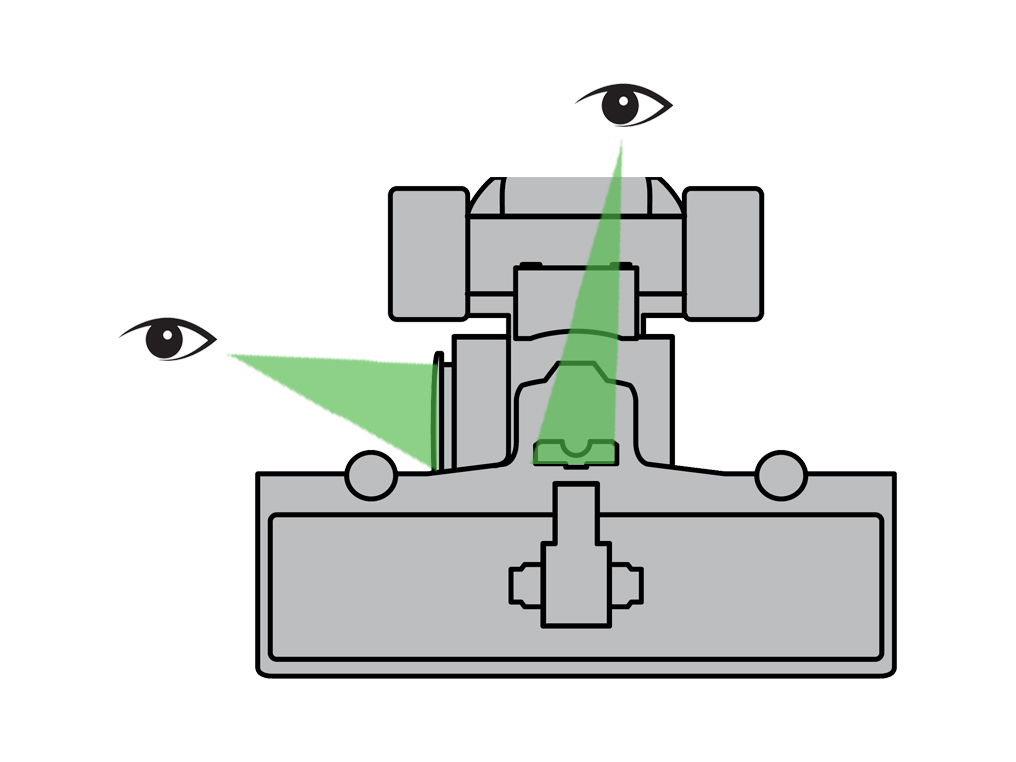

Check the Turbine head has the correct setting for your type of floor.

Pull plunger out for the Brush bar to spin (for carpet cleaning).

Push plunger in for to stop the Brush bar spinning (for hard floors or delicate surfaces).

Retest the machine.

Has checking the floor tool resolved the problem?

Cleaning the bin and cyclone

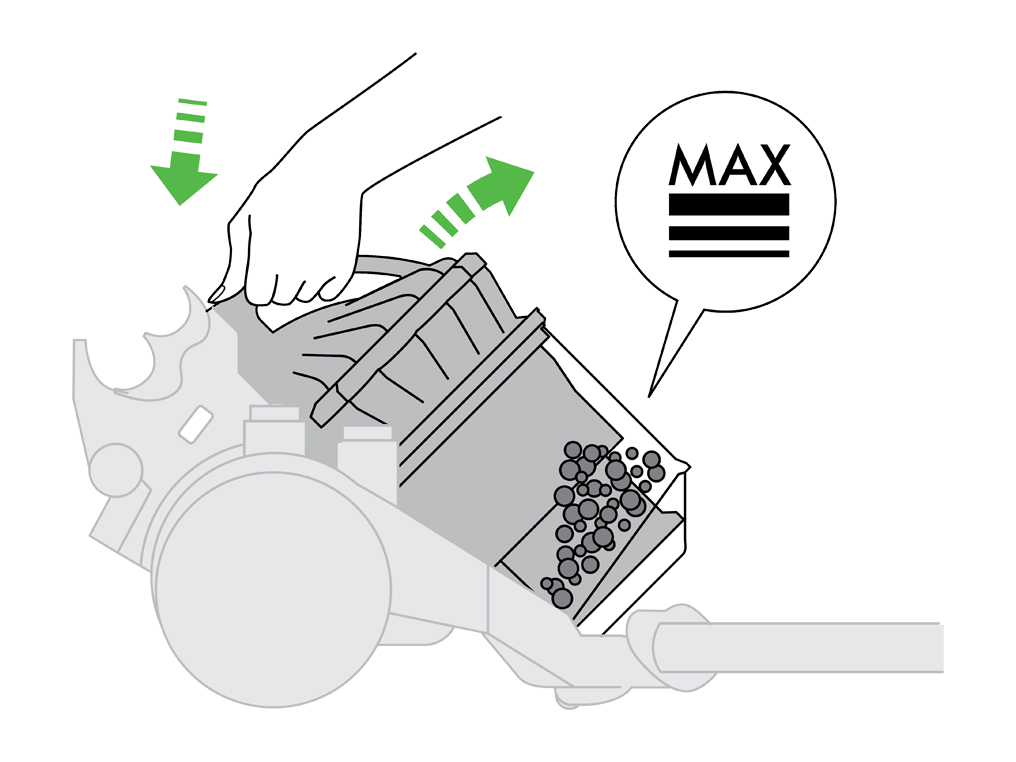

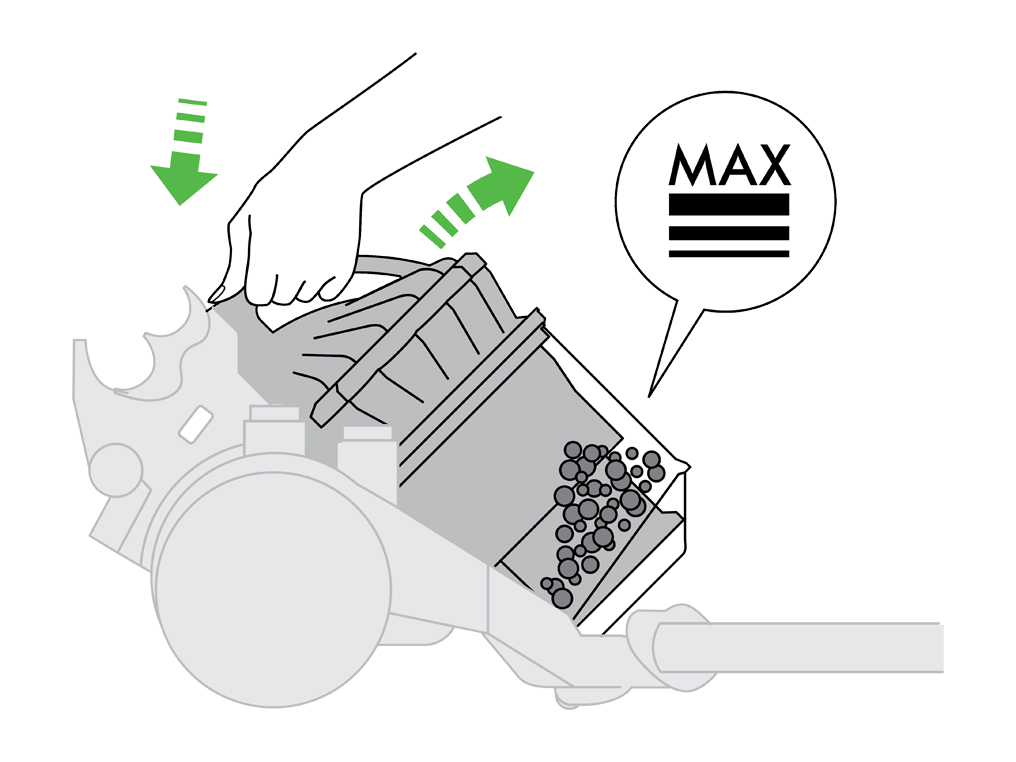

Empty as soon as the dirt reaches the level of the MAX mark.

Removing the bin.

To remove the cyclone and clear bin, push the release button at the top of the cyclone handle. Remove the cyclone and clear bin.

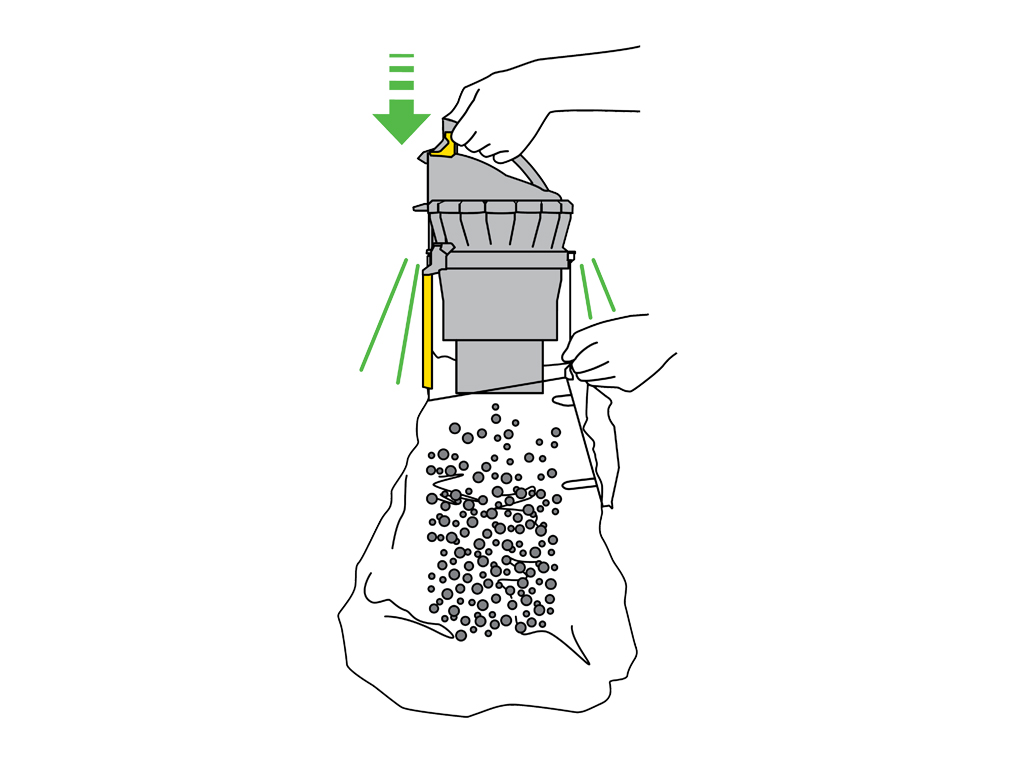

Emptying the bin

To detach the bin from the cyclone, press the release catch on the clear bin handle.

NB: To minimise dust/allergen contact when emptying, encase the clear bin tightly in a plastic bag and empty. Remove the clear bin carefully. Seal the bag tightly, dispose as normal.

Clean the cyclone shroud

Clean with a dry cloth or brush to remove fluff and debris.

Tap the cyclone gently to help displace any fine dust.

Check the bin and cyclone

Check the bin seal is not missing or damaged.

Check the duct for blockages.

Refit the bin

Reassemble the bin and cyclone.

Replace onto the Main body, ensuring it clicks into place.

Please select the appropriate option

Please select the appropriate option

What type of noise?

Test the machine without the bin

Press the bin release catch.

Remove the bin and cyclone from the Main body.

Turn the machine on.

Clean the bin and cyclone

Empty as soon as the dirt reaches the level of the MAX mark.

Removing the bin.

To remove the cyclone and clear bin, push the release button at the top of the cyclone handle. Remove the cyclone and clear bin.

Emptying the bin

Disconnect the bin and cyclone by pressing the release catch on the clear bin handle.

NB: To minimise dust/allergen contact when emptying, encase the clear bin tightly in a plastic bag and empty. Remove the clear bin carefully. Seal the bag tightly, dispose as normal.

Clean the cyclone shroud

Clean with a dry cloth or brush to remove fluff and debris.

WARNING: Do not use water.

Bin and cyclone checks

Ensure the bin inner seal is not missing or damaged. If so choose 'Part broken'.

Check there are no blockages through the centre of the cyclone or inlet located at the top.

Refit the bin, connecting the back of the clear bin to the cyclone first and clicking at the front last.

Ensure a tight seal, any gaps would cause a loss of performance and may not reconnect with the Main body.

Replace the bin and cyclone to the Main body, ensuring it clicks into place.

Retest the machine.

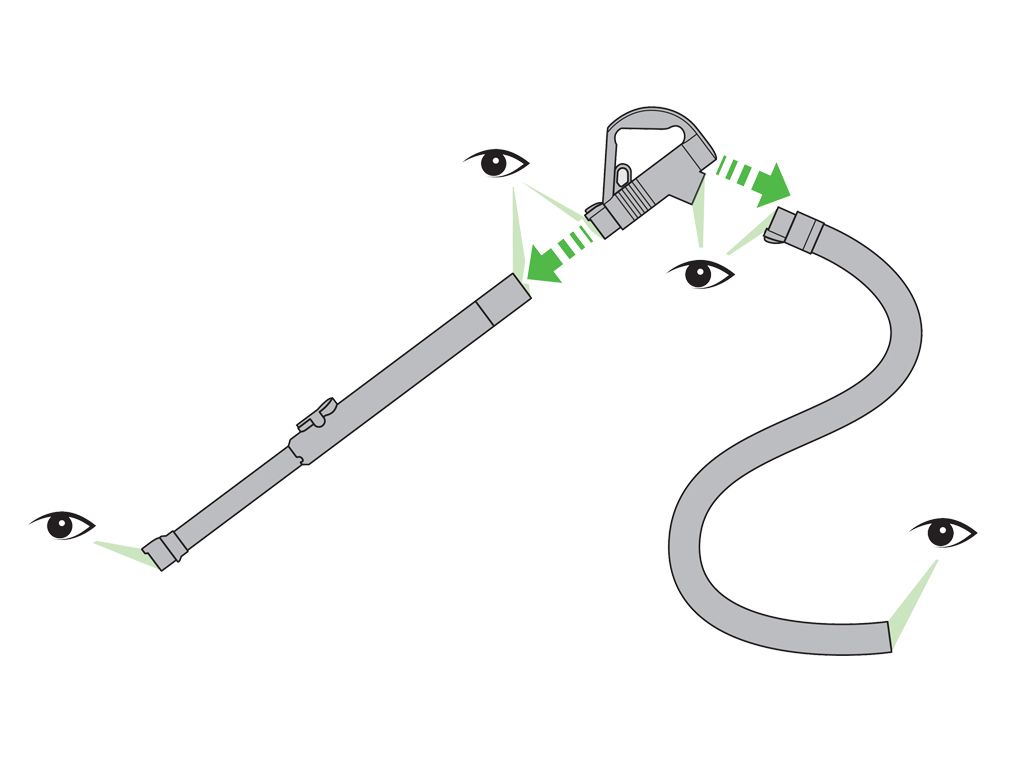

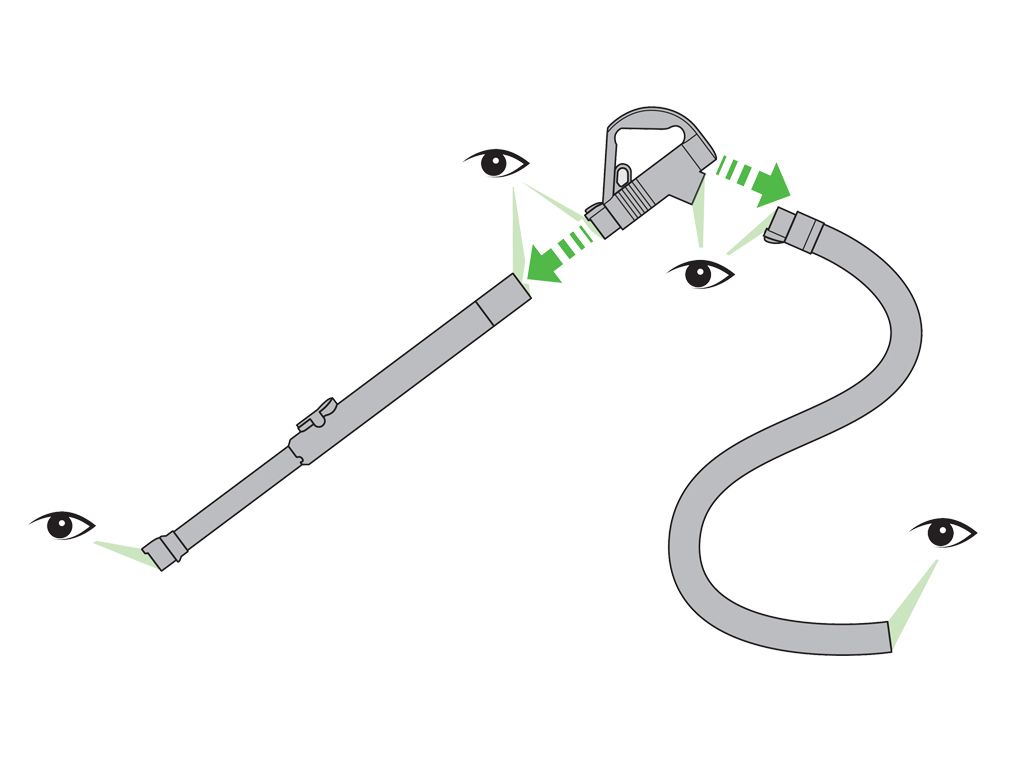

Check extension tube, wand handle and hose

Remove the hose from the Main body.

Pull hose out of the inlet.

Press back cuff release catch and remove from the Main body.

Detach the Wand handle from the hose and extension tube.

Check for blockages and remove as necessary

Check for blockages and remove as necessary.

Check both ends of the flexible hose.

Check both ends of the Wand handle.

Check both ends of the extension tube.

Reassemble and test the machine.

Check the floor tool

Press the release button on the Turbine head to remove from the Extension tube.

Slide back the soleplate catch and turn the two fasteners by a quarter.

Check for blockages

Remove the Brush bars and clear any hair, thread and debris

Check both of the metal shafts for blockages and ensure they rotate freely by hand

Inspect the duct on the underside of the Turbine head for blockages and remove if necessary.

Check the outside surface of the plunger for fluff and debris and remove if necessary.

Check the outside surface of the plunger for fluff and debris and remove if necessary.

When replacing the Brush bars please ensure that both the arrows on the Brush bars are pointing in the same direction towards the wheels on the Turbine head.

Replace soleplate locking the front tabs first and reclining the soleplate down, lock the two fasteners and slide back the soleplate catch.

Check the Turbine head has the correct setting for your type of floor.

Pull plunger out for the Brush bar to spin (for carpet cleaning).

Push plunger in for to stop the Brush bar spinning (for hard floors or delicate surfaces).

Retest the machine.

Has checking the floor tool resolved the problem?

Check hose inlet

If your machine is making a whistling noise, this indicates that there is a blockage or a damaged or missing seal.

Remove the hose from the hose inlet on the front of the machine.

Place your hand over the hose inlet and test the suction.

Is the suction strong or weaker than usual?

Check hose, Wand handle and extension tube

Ensure that the extension tube is fully extended.

Unclip the hose from the hose inlet.

Separate the wand handle from the hose and extension tube.

Check inside the Wand handle and along the length of the hose and extension tube for blockages and remove as necessary.

Which tool are you using?

Turbine head.

Dual mode floor tool.

Contact head.

Which floor tool are you using?

Check the Turbine head

Slide back the soleplate catch and undo the 2 soleplate fasteners.

Remove the soleplate and Brush bars from the Turbine head, clearing any thread and debris.

Check both of the metal shafts for blockages and ensure that they rotate freely by hand.

Check the underside of the Turbine head and the outside surface of the plunger for fluff and debris and remove as necessary. The plunger must be in the 'out' position for the Brush bar to spin.

When replacing the Brush bars please ensure that both the arrows on the Brush bars are pointing in the same direction towards the wheels on the Turbine head.

Rebuild and test the machine.

Continue with checks

The Brush bar should spin if the suction is strong, so please continue with the performance checks.

If the suction is strong and the Brush bar still doesn't spin, this issue can be resolved by ordering a replacement Turbine head.

Please select the appropriate option

Check duct, bin and cyclone

Turn the power off and unplug the machine.

Press the release catch on the cyclone assembly and remove the cyclone and clear bin from the machine.

Check the duct

Check the seals located on the hose inlet and exhaust pipe are not missing or damaged.

Check the hose inlet and exhaust pipe for any blockages and remove as necessary.

Check the cyclone top and bin entry for blockages and remove as necessary.

Push the button on top of the cyclone to open the bin lid, being careful to ensure dust is captured.

Shake or tap firmly to remove all dust from inside the fine dust collector.

Release the clear bin from the cyclone by pressing the button on the back of the cyclone.

Clean the cyclone with a dry cloth and shake or tap firmly to remove all dust from inside the fine dust collector. Check the cyclone and bin seals are not missing or damaged.

If any parts are missing or damaged, select 'part broken'.

Reassemble and test the machine.

Check the Dual mode floor tool

Check the base and connector of the Dual mode floor tool for blockages and remove as necessary.

Test the Dual mode floor tool on the machine.

Check the contact head

Check the base and opening of the contact head for blockages and remove as necessary.

Test the contact head on the machine.

Check duct, bin and cyclone

Turn the power off and unplug the machine.

Press the button at the top of the cyclone handle and remove the bin from the machine.

Check the duct

Check the hose inlet and exhaust pipe for any blockages and remove as necessary.

Check the hose inlet and exhaust pipe for any blockages and remove as necessary.

Check the hose inlet and exhaust pipe for any blockages and remove as necessary.

Push the button on top of the cyclone to open the bin lid, being careful to ensure dust is captured.

Shake or tap firmly to remove all dust from inside the fine dust collector.

Release the clear bin from the cyclone by pressing the button on the back of the cyclone.

Clean the cyclone with a dry cloth and shake or tap firmly to remove all dust from inside the fine dust collector. Check the cyclone and bin seals are not missing or damaged.

If any parts are missing or damaged, select 'part broken'.

Reassemble and test the machine.

Check hose, Wand handle and extension tube

Ensure that the extension tube is fully extended.

Unclip the hose from the hose inlet.

Separate the wand handle from the hose and extension tube.

Check inside the Wand handle and along the length of the hose and extension tube for blockages and remove as necessary.

Which tool are you using?

Turbine head.

Dual mode floor tool.

Contact head.

Which floor tool are you using?

Check the Dual mode floor tool

Check the base and connector of the Dual mode floor tool for blockages and remove as necessary.

Test the Dual mode floor tool on the machine.

Check the contact head

Check the base and opening of the contact head for blockages and remove as necessary.

Test the contact head on the machine.

Check the Turbine head

Slide back the soleplate catch and undo the 2 soleplate fasteners.

Remove the soleplate and Brush bars from the Turbine head, clearing any thread and debris.

Check both of the metal shafts for blockages and ensure that they rotate freely by hand.

Check the underside of the Turbine head and the outside surface of the plunger for fluff and debris and remove as necessary. The plunger must be in the 'out' position for the Brush bar to spin.

When replacing the Brush bars please ensure that both the arrows on the Brush bars are pointing in the same direction towards the wheels on the Turbine head.

Rebuild and test the Turbine head on the machine.

Has checking the floor tool resolved the problem?

Test the suction from the extension tube

Remove the floor tool from the extension tube by pressing the release catch on the end of the extension tube.

Grip cuff firmly to extend extension tube fully, ensuring it can extend no further.

Place your hand over the end of the extension tube and test the suction.

Is the suction strong or weaker than usual?

Check the floor tool

Press the release button on the Turbine head to remove from the Extension tube.

Slide back the soleplate catch and turn the two fasteners by a quarter.

Check for blockages

Remove the Brush bars and clear any hair, thread and debris

Check both of the metal shafts for blockages and ensure they rotate freely by hand

Inspect the duct on the underside of the Turbine head for blockages and remove if necessary.

Check the outside surface of the plunger for fluff and debris and remove if necessary.

Check the outside surface of the plunger for fluff and debris and remove if necessary.

When replacing the Brush bars please ensure that both the arrows on the Brush bars are pointing in the same direction towards the wheels on the Turbine head.

Replace soleplate locking the front tabs first and reclining the soleplate down, lock the two fasteners and slide back the soleplate catch.

Check the Turbine head has the correct setting for your floor

Pull plunger out for the Brush bar to spin (for carpet cleaning).

Push plunger in for to stop the Brush bar spinning (for hard floors or delicate surfaces).

Retest the machine.

Please select the appropriate option

When did the machine last have power?

Thermal cut out

Most Dyson vacuums have a built in safety system that stops the machine if it begins to overheat. This usually happens because the filters need washing or your machine is blocked.

Carry out the performance checks, and if your machine cuts out unplug and leave for at least 2 hours to cool down.

Please select the appropriate option

Check electrical supply

- Is the power cord or plug damaged?

- Are the other household appliances working?

- Does the vacuum work when plugged into another socket?

The switch does not light up.

Press the switch

Press the rear of the switch to make sure it stays in the on position.

Please select the appropriate option

What sort of smell?

Wash the filters and clean the bin

This issue can be resolved by washing the filters and cleaning the bin and cyclone.

Checking the duct, cyclone and bin

Remove the bin by pressing the catch on top of the handle.

Remove the cyclone from the bin by pressing the release catch on top of the clear handle.

Clean the shroud with a cloth or dry brush to remove the fluff and dust.

Check the bin and cyclone

Ensure the bin inner is clear and large cone seal is not missing or damaged.

Ensure the cyclone is clean and remove blockages as necessary. Tap cyclone to remove tougher debris.

Checking the duct

Check the duct inlet for blockages and remove as necessary.

Open the pre-filter cover and remove blockages as necessary.

Close the pre-filter cover lid ensuring the filter is inside, reconnect the bin and cyclone and attach to the machine.

If any parts are missing or damaged choose part broken to place an order.

Retest the machine.

Please select the appropriate option

Using the cable

Ensure the machine is switched off.

Unplug the machine before rewinding the cable.

If the cable does not rewind, firmly pull it out and fully extend it until the red tape is visible.

The cord rewind button needs to be pressed down firmly to retract the cord for storage after use. When the button is pressed down far enough you should feel and hear a click, and the cord will retract.

Any non-domestic use may adversely affect the filter performance such as vacuuming up builders dust.

Wash the filters and check for blockages

This usually happens because the filters need washing or your machine is blocked.

Remember to turn the power off and unplug the machine before you check the filters and look for blockages prior to restarting the machine.

Please select the appropriate option

Washing the filter

Please follow the steps in the video to wash the filter.

If washing the filter doesn't resolve the issue, please select Cleaning the bin and cyclone.

For a step by step guide, please select step by step.

Is there anything else we can help with?

Filter washing

Turn power off and unplug the machine.

The post-motor filter located under the clear bin should last the lifetime of the machine and does not need to be washed.

Press the release catch on the cyclone and remove the filter and filter casing from the machine.

Wash the filter in cold water only.

WARNING: Please do not use detergent, do not wash in a dishwasher or washing machine.

Wash the filter with cold water only.

Leave the filter to dry in a warm place for 12 hours, until completely dry.

Do not dry the filter in a tumble dryer, microwave, oven or near a naked flame.

The filter should be washed at least once every 6 months.

If the filter is missing or damaged choose 'part broken'.

Please select the appropriate option

Please select the appropriate option

Please select the appropriate option

Please select the appropriate option

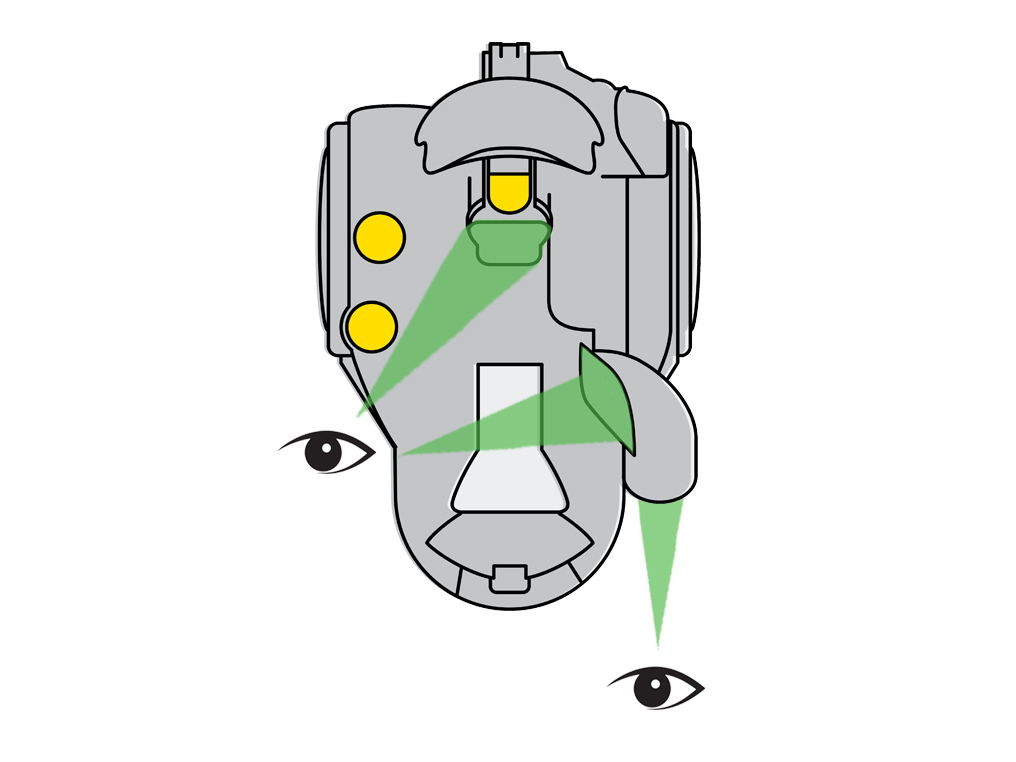

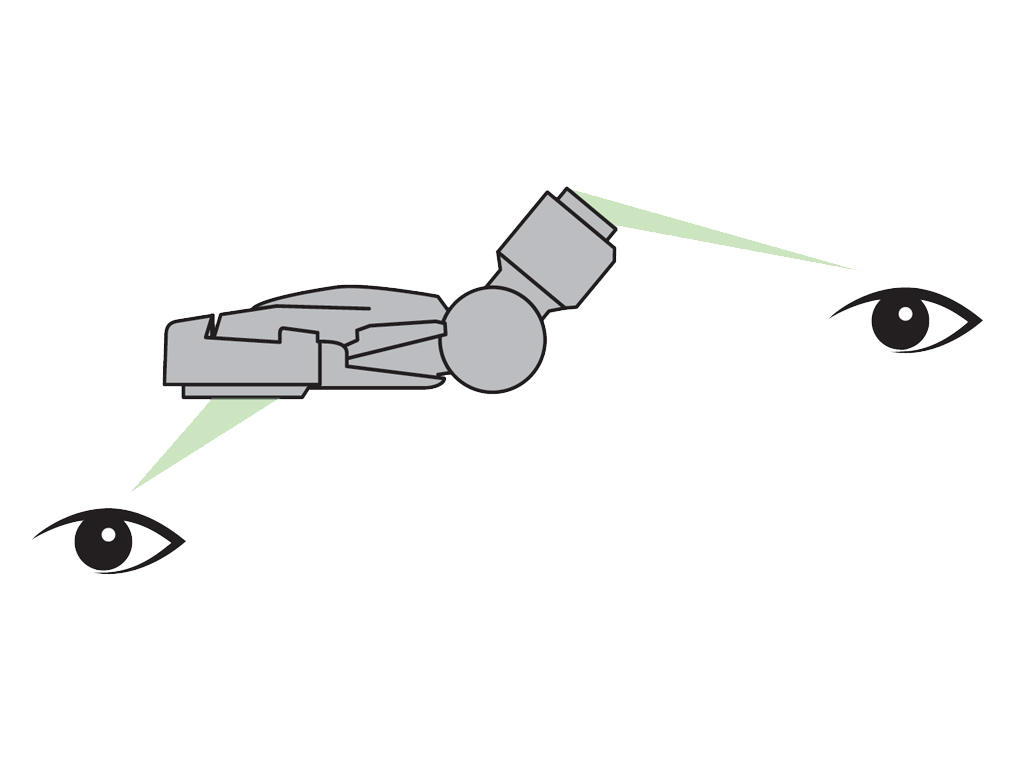

Test the suction from the extension tube

The image may show a different floor tool variant although the process remains the same.

Remove the floor tool from the extension tube.

Press the release catch on the extension tube to extend fully, ensuring it 'clicks' into place.

Place your hand over the end of the extension tube and test the suction.

Is the suction strong or weaker than usual?

Check for blockages

Remove the hose from the Main body.

Pull hose out of the inlet.

Press back cuff release catch and remove from the Main body.

Disconnect the Wand from the hose.

Check for blockages and remove as necessary

Check both ends of the flexible hose and the Wand for blockages and remove as necessary.

If any parts are missing or damaged choose part broken to place an order.

Retest the machine.

Checking the duct, cyclone and bin

Remove the bin by pressing the catch on top of the handle.

Remove the cyclone from the bin by pressing the release catch on top of the clear handle.

Clean the shroud with a cloth or dry brush to remove the fluff and dust.

Check the bin and cyclone

Ensure the bin inner is clear and large cone seal is not missing or damaged.

Ensure the cyclone is clean and remove blockages as necessary. Tap cyclone to remove tougher debris.

Checking the duct

Check the duct inlet for blockages and remove as necessary.

Open the pre-filter cover and remove blockages as necessary.

Close the pre-filter cover lid ensuring the filter is inside, reconnect the bin and cyclone and attach to the machine.

If any parts are missing or damaged choose part broken to place an order.

Retest the machine.

The post-motor filter located under the clear bin should last the lifetime of the machine and does not need to be washed.

Remove the filters

Turn power off and unplug the machine.

Press the release catch on the cyclone and remove the filter and filter casing from the machine.

Wash the filter in cold water only.

WARNING: Please do not use detergent, do not wash in a dishwasher or washing machine.

Wash the filter case in cold water only.

Dry the filter

Leave the filter to dry in a warm place for 12 hours, until completely dry.

Do not dry the filter in a tumble dryer, microwave, oven or near a naked flame.

The filter should be washed at least once every 6 months.

If the filter is missing or damaged choose 'part broken'.

Check the floor tool

Remove the floor tool from the metal extension tube by pressing the push button located on the floor tool.

Check the opening of the floor tool for blockages and remove if necessary.

You can change the resistance of the floor tool by adjusting the red airflow ports on its base.

Push the tabs inwards to ensure best resistance.

Reassemble and test the machine.

If the floor tool is damaged choose the 'part broken' option.

Has checking the floor tool resolved the problem?

Check the floor tool

Press the release button on the Turbine head to remove from the Extension tube.

Slide back the soleplate catch and turn the two fasteners by a quarter.

Check for blockages

Remove the Brush bars and clear any hair, thread and debris

Check both of the metal shafts for blockages and ensure they rotate freely by hand

Inspect the duct on the underside of the Turbine head for blockages and remove if necessary.

Check the outside surface of the plunger for fluff and debris and remove if necessary.

Check the outside surface of the plunger for fluff and debris and remove if necessary.

When replacing the Brush bars please ensure that both the arrows on the Brush bars are pointing in the same direction towards the wheels on the Turbine head.

Replace the soleplate, locking the front tabs first and reclining the soleplate down. Lock the two fasteners and slide back the soleplate catch.

Check the Turbine head has the correct setting for your floor

Pull plunger out for the Brush bar to spin (for carpet cleaning).

Push plunger in for to stop the Brush bar spinning (for hard floors or delicate surfaces).

Retest the machine.

Check for blockages

Remove the hose from the Main body.

Pull hose out of the inlet.

Press back cuff release catch and remove from the Main body.

Detach the Wand handle from the hose.

Check for blockages and remove as necessary.

Check both ends of the flexible hose.

Check both ends of the Wand handle.

Reassemble and test machine.

Checking the duct, cyclone and bin

Remove the bin by pressing the catch on top of the handle.

Remove the cyclone from the bin by pressing the release catch on top of the clear handle.

Clean the shroud with a cloth or dry brush to remove the fluff and dust.

Check the bin and cyclone

Ensure the bin inner is clear and large cone seal is not missing or damaged.

Ensure the cyclone is clean and remove blockages as necessary. Tap cyclone to remove tougher debris.

Checking the duct

Check the duct inlet for blockages and remove as necessary.

Open the pre-filter cover and remove blockages as necessary.

Close the pre-filter cover lid ensuring the filter is inside, reconnect the bin and cyclone and attach to the machine.

If any parts are missing or damaged choose part broken to place an order.

Retest the machine.

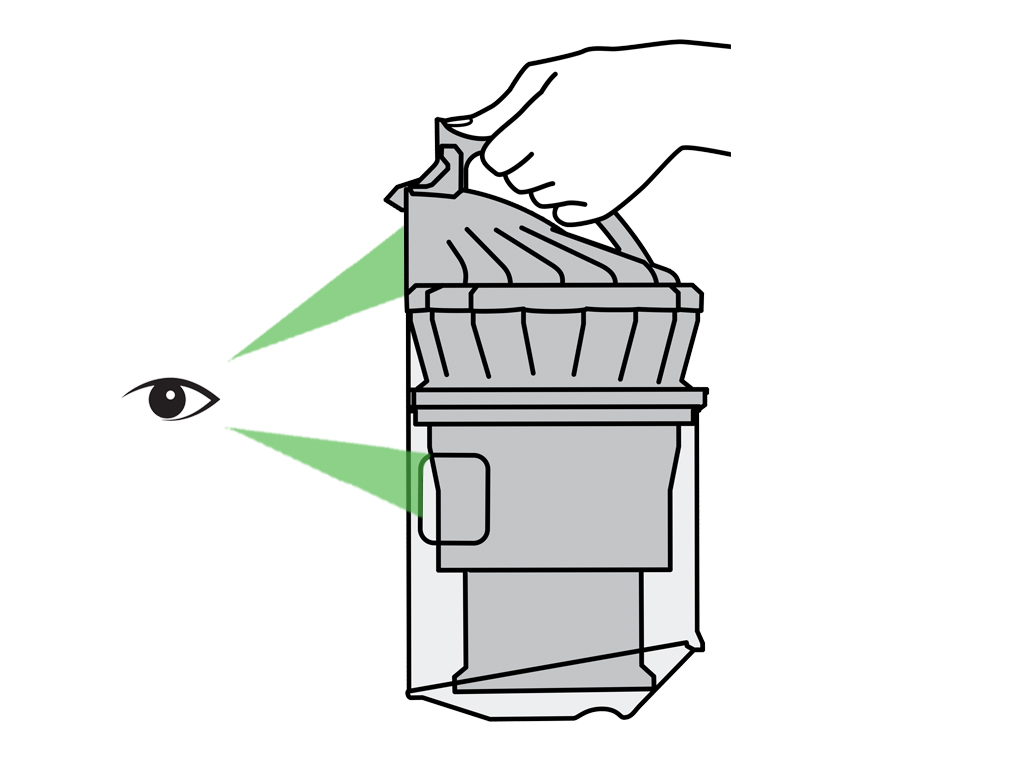

Cleaning the bin and cyclone

Empty as soon as the dirt reaches the level of the MAX mark.

Removing the bin.

To remove the cyclone and clear bin, push the release button at the top of the cyclone handle. Remove the cyclone and clear bin.

Emptying the bin

To detach the bin from the cyclone, press the release catch on the clear bin handle.

NB: To minimise dust/allergen contact when emptying, encase the clear bin tightly in a plastic bag and empty. Remove the clear bin carefully. Seal the bag tightly, dispose as normal.

Clean the cyclone shroud

Clean with a dry cloth or brush to remove fluff and debris.

Tap the cyclone gently to help displace any fine dust.

Check the bin and cyclone

Check the bin seal is not missing or damaged.

Check the duct for blockages.

Refitting the bin

Reassemble the bin and cyclone.

Replace onto the Main body, ensuring it clicks into place.

Cleaning the bin and cyclone

Empty as soon as the dirt reaches the level of the MAX mark.

Removing the bin.

To remove the cyclone and clear bin, push the release button at the top of the cyclone handle. Remove the cyclone and clear bin.

Emptying the bin

To detach the bin from the cyclone, press the release catch on the clear bin handle.

NB: To minimise dust/allergen contact when emptying, encase the clear bin tightly in a plastic bag and empty. Remove the clear bin carefully. Seal the bag tightly, dispose as normal.

Clean the cyclone shroud

Clean with a dry cloth or brush to remove fluff and debris.

Tap the cyclone gently to help displace any fine dust.

Check the bin and cyclone

Check the bin seal is not missing or damaged.

Check the cyclone is clear of blockages through the middle and the top inlet.

Washing the bin

WARNING: Use water only and no detergents.

Ensure bin is completely dry before placing back onto the machine.

Do not remove rubber seals.

Refitting the bin

Reassemble the bin and cyclone.

Replace onto the Main body, ensuring it clicks into place.

Washing the filter

Please follow the steps in the video to wash the filter.

If washing the filter doesn't resolve the issue, please select Cleaning the bin and cyclone.

For a step by step guide, please select step by step.

Is there anything else we can help with?

Filter washing

Turn power off and unplug the machine.

The post-motor filter located under the clear bin should last the lifetime of the machine and does not need to be washed.

Press the release catch on the cyclone and remove the filter and filter casing from the machine.

Wash the filter in cold water only.

WARNING: Please do not use detergent, do not wash in a dishwasher or washing machine.

Wash the filter in cold water only.

Leave the filter to dry in a warm place for 12 hours, until completely dry.

Do not dry the filter in a tumble dryer, microwave, oven or near a naked flame.

The filter should be washed at least once every 6 months.

If the filter is missing or damaged choose 'part broken'.

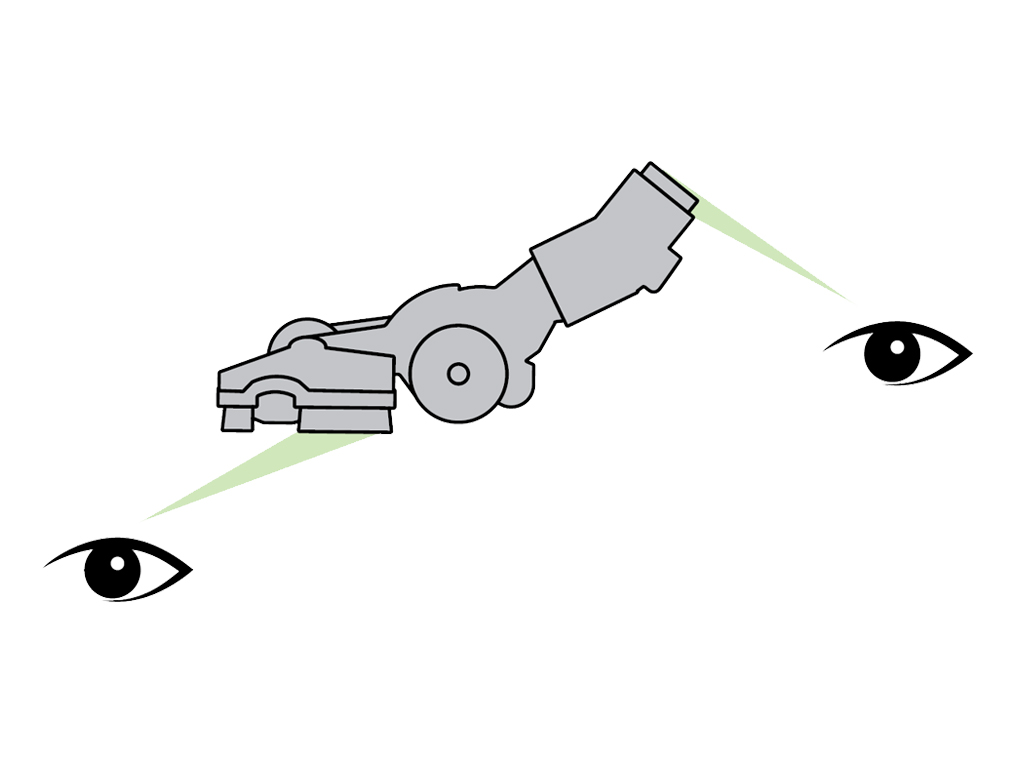

Finding serial number

The serial number can be found on the rating plate, underneath the machine, between the two wheels.

How to attach the accessories

Attach the accessories or floor tool to the extension tube ensuring they 'click' into place.

Alternatively, remove the extension tube and attach the accessory tools directly to the hose.

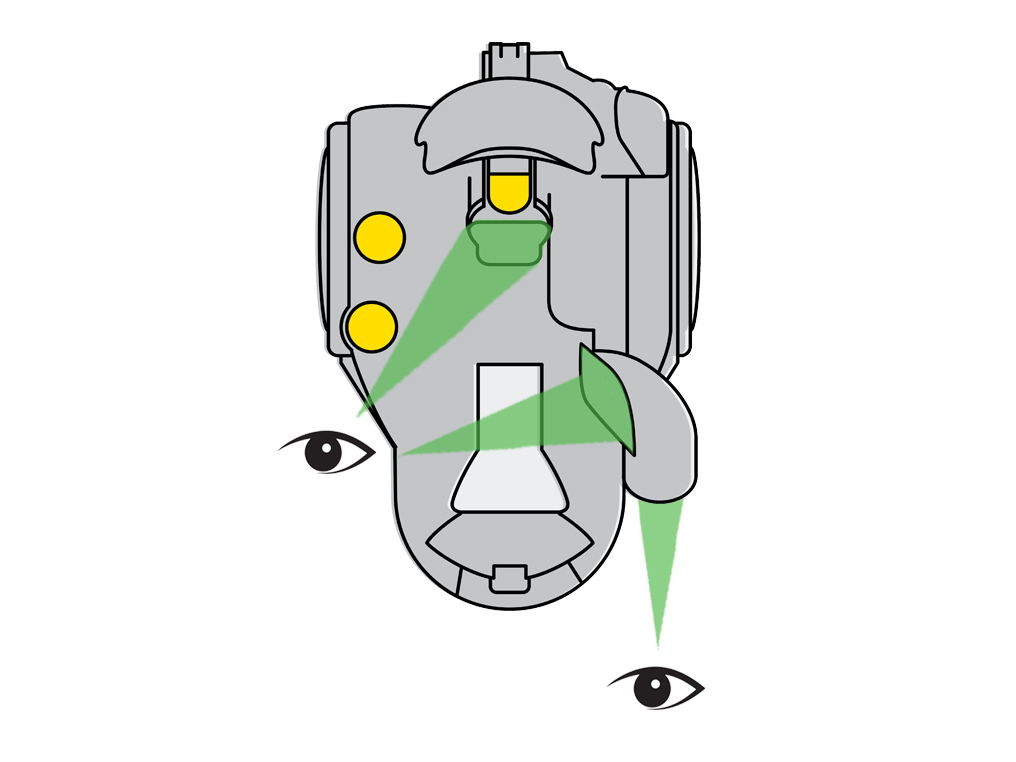

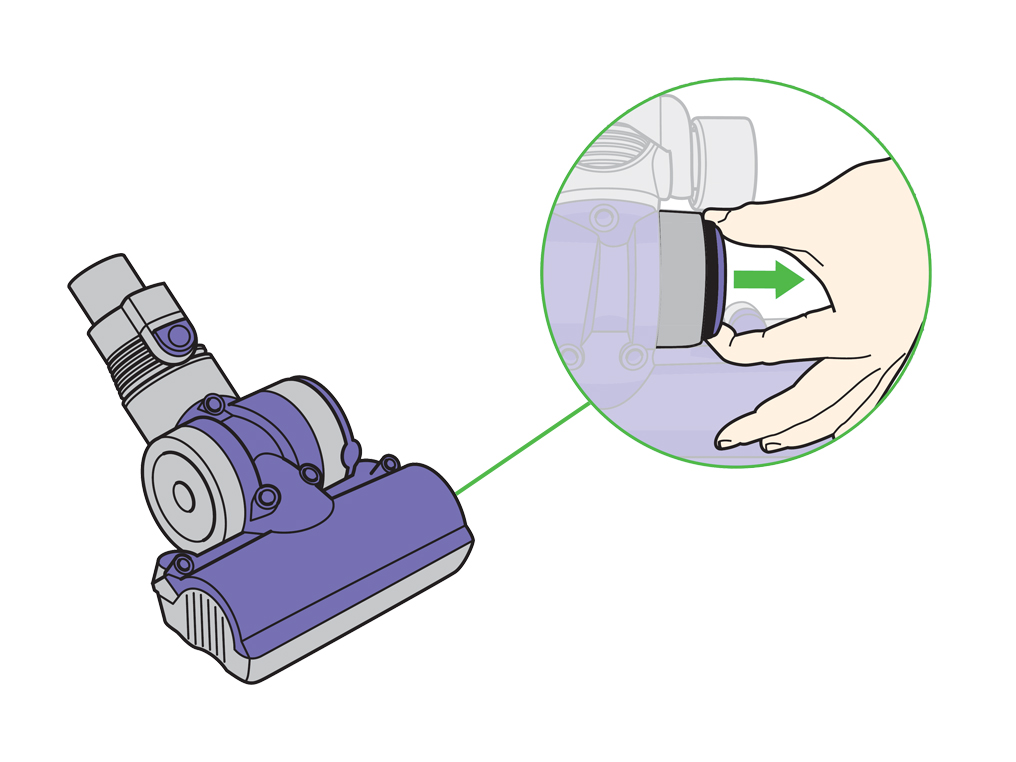

Using the Mini turbine head

The Brush bar can be turned on and off by using the plunger on the side of the Mini turbine head.

Brush bar turned on for carpets.

Brush bar turned off for hard or delicate flooring.

If the Brush bar does not spin please select the appropriate option.

How to use the telescope wand

You can use the Wand collapsed and add accessory tools.

If you press the release catch over the top of the wand, you can extend the first section by small increments.

To use with the main floor tool we recommend fully extending the telescope.

Check the floor tool

Press the release button on the Turbine head to remove from the Extension tube.

Slide back the soleplate catch and turn the two fasteners by a quarter.

Check for blockages

Remove the Brush bars and clear any hair, thread and debris

Check both of the metal shafts for blockages and ensure they rotate freely by hand

Inspect the duct on the underside of the Turbine head for blockages and remove if necessary.

Check the outside surface of the plunger for fluff and debris and remove if necessary.

Check the outside surface of the plunger for fluff and debris and remove if necessary.

When replacing the Brush bars please ensure that both the arrows on the Brush bars are pointing in the same direction towards the wheels on the Turbine head.

Replace the soleplate, locking the front tabs first and reclining the soleplate down. Lock the two fasteners and slide back the soleplate catch.

Check the Turbine head has the correct setting for your type of floor.

Pull plunger out for the Brush bar to spin (for carpet cleaning).

Push plunger in for to stop the Brush bar spinning (for hard floors or delicate surfaces).

Retest the machine.

Check Mini turbine head

Undo both fasteners on the soleplate by a quarter.

Check for blockages

Remove each side of the Brush bar by sliding each half out from the sides of the Mini turbine head.

Clear any thread and debris.

Check both of the metal shafts for blockages and ensure that they rotate freely by hand.

Inspect the duct on the underside of the Turbine head for blockages and remove as necessary.

Check the outside surface of the plunger for fluff and debris and remove as necessary.

When replacing the Brush bars please ensure that both of the arrows on the Brush bars are pointing in the same direction, towards the rear of the tool.

Reassemble both Brush bar parts to the metal shafts.

Re-assemble the soleplate ensuring that it is flush and fasteners are locked.

Pull out the plunger to allow Brush bar to spin.

If there is any damage to the Mini turbine head choose 'part broken' to place an order.

Retest the machine.

Has checking the Mini turbine head resolved the problem?

Blockage issue

The Mini turbine head will need strong suction to allow the Brush bar to spin.

There could be a blockage causing a loss of performance.

Please select the appropriate option

Test the suction from the extension tube

Remove the floor tool from the extension tube by pressing the release catch on the floor tool.

Grip cuff firmly to extend extension tube fully, ensuring it can extend no further.

Place your hand over the end of the extension tube and test the suction.

Is the suction strong or weaker than usual?

Check for blockages

Remove the hose from the Main body.

Pull hose out of the inlet.

Press back cuff release catch and remove from the Main body.

Detach the Wand handle from the hose and extension tube.

Check for blockages and remove as necessary

Check for blockages and remove as necessary.

Check both ends of the flexible hose.

Check both ends of the Wand handle.

Check both ends of the extension tube.

Reassemble and test the machine.

Please select the appropriate option

Finding serial number

The serial number can be found on the rating plate, underneath the machine, between the two wheels.

How to attach the accessories

Attach the accessories or floor tool to the extension tube ensuring they 'click' into place.

Alternatively, remove the extension tube and attach the accessory tools directly to the hose.

Using the Mini turbine head

The Brush bar can be turned on and off by using the plunger on the side of the Mini turbine head.

Brush bar turned on for carpets.

Brush bar turned off for hard or delicate flooring.

If the Brush bar does not spin please select the appropriate option.

Extension tube

Grip cuff firmly to extend extension tube.

Cleaning the bin and cyclone

Empty as soon as the dirt reaches the level of the MAX mark.

Removing the bin.

To remove the cyclone and clear bin, push the release button at the top of the cyclone handle. Remove the cyclone and clear bin.

Emptying the bin

To detach the bin from the cyclone, press the release catch on the clear bin handle.

NB: To minimise dust/allergen contact when emptying, encase the clear bin tightly in a plastic bag and empty. Remove the clear bin carefully. Seal the bag tightly, dispose as normal.

Clean the cyclone shroud

Clean with a dry cloth or brush to remove fluff and debris.

Tap the cyclone gently to help displace any fine dust.

Check the bin and cyclone

Check the bin seal is not missing or damaged.

Check the cyclone is clear of blockages through the middle and the top inlet.

Washing the bin

Use water only and no detergents.

Ensure bin is completely dry before placing back onto the machine.

Do not remove rubber seals.

Refitting the bin

Reassemble the bin and cyclone.

Replace onto the Main body, ensuring it clicks into place.

Further help

DC08 Allergy™